Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Week 5 Challenge : Surface wrap on Automotive Assembly

QUESTION - Surface Wrap the automotive assembly by performing topo clean-up. Write down a detailed report mentioning the entire process. Also, include the concepts you learned. Target length for Wrap = 3 mmANSWER - Final Geometry File - https://drive.google.com/file/d/14taH6kj9bw5JHtIhsfvuto0zKPCCEmXz/view?usp=sharingAim…

Bhavesh Kumbhare

updated on 09 Oct 2022

QUESTION -

Surface Wrap the automotive assembly by performing topo clean-up. Write down a detailed report mentioning the entire process. Also, include the concepts you learned.

Target length for Wrap = 3 mm

ANSWER -

Final Geometry File - https://drive.google.com/file/d/14taH6kj9bw5JHtIhsfvuto0zKPCCEmXz/view?usp=sharing

Aim -

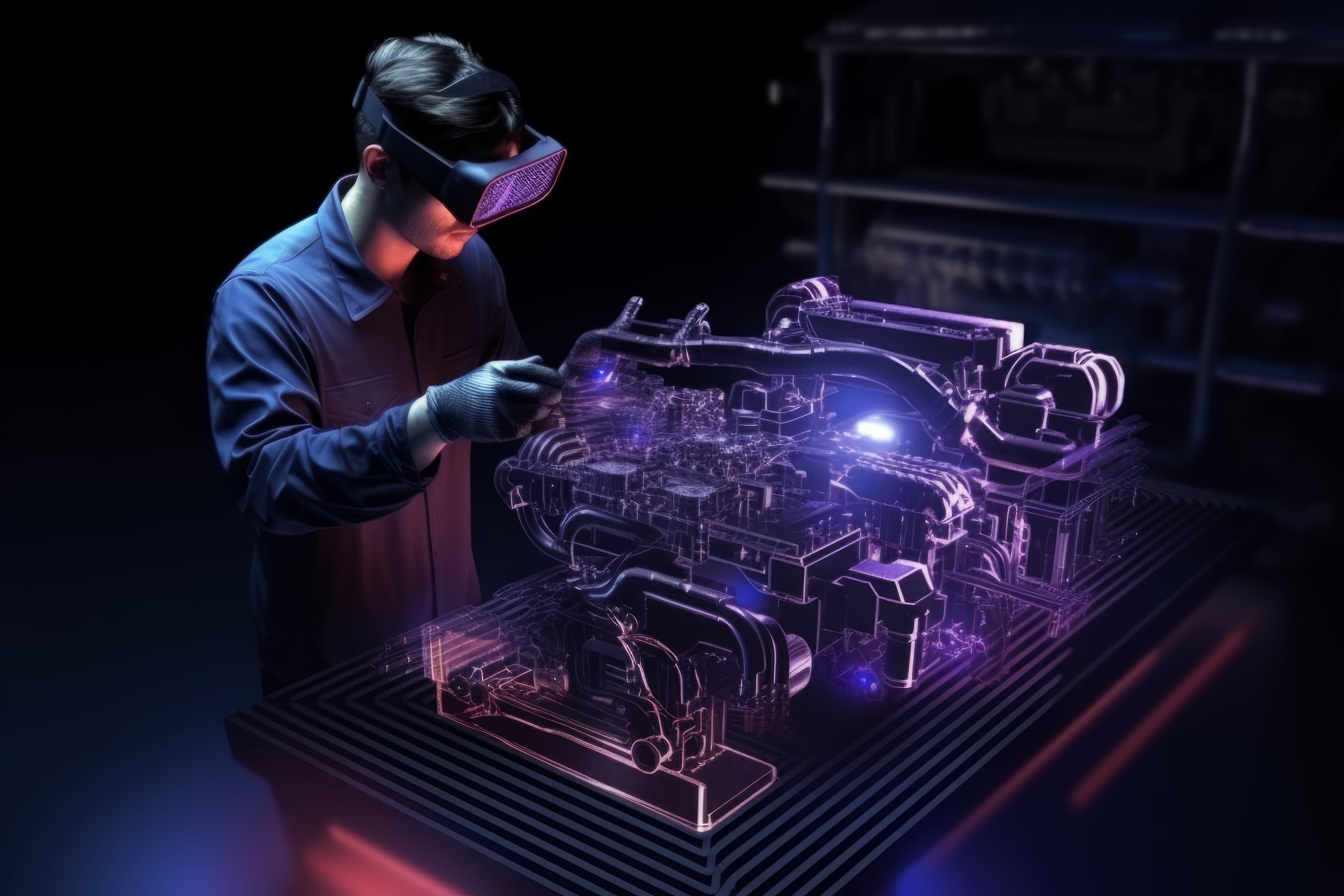

To perform surface wrap of the given geometry of an automobile assembly consisting of three different components (models) in the ANSA pre-processor according to the given conditions. ANSA is a popular computer-aided engineering tool for CFD and Finite Element Analysis in the automobile sector.

Procedure -

Surface Wrap of any geometry means to mesh it from outside, that is, the meshing of only the external surfaces. It does not deal with the surfaces present inside, hence we would not be concerned with the internal surfaces of the geometry provided.

There are three components provided in the automotive assembly -

- Engine Model

- Transmission Model

- Gearbox Model

Here, in this challenge, we will have to clean up the external surfaces of all three geometry individually. After cleanup, we will merge all three models and make a single assembly in one interface. Later, we will perform surface wrap on the entire single geometry.

Steps -

- Topo Clean-up

Here, we are working in the "Topo Deck" by default.

Engine Model -

We will delete all the unnecessary surfaces of the geometry which includes all the ring-like surfaces and the overlapping surfaces. "Isolating all the prominent parts and then deleting the unnecessary parts would make the task easier."

Note - Triple cones will not cause any problems in the surface wrap. We just need to delete the red cones, especially which are on the external surfaces.

Conveyor belts may be deleted as they are thin and would not capture completely in the surface wrap.

Transmission Model & Gearbox Model -

Deleting all the unnecessary parts and fixing the geometry will accomplish our Topo clean-up.

- Merging all three Models

Here, the Gearbox model is opened in our interface.

File > Merge > select the other two model > click Open > OK

Repeat this for the third remainder model.

For the good quality surface wrap, we need to close all the open faces.

- Surface Wrap

Before performing the surface wrap, ensure that we have only the necessary PIDs. Use the "Compress" tool to delete unnecessary PIDs.

Click the "Classic Mesh" Deck.

Elements > Wrap > Constant Length

In Parameters:

Set the target length as "3 mm".

In Contents:

Select all the PIDs and click the 'Green Arrow'. Click OK.

Click "Run" and wait for a few minutes to generate the wrap. Thus, the surface wrap is accomplished.

Note - Set the target length depending upon the requirement of the wrap. A good quality wrap will consume more computational time and will require a small target length, while if the concern is the computational time one should use a larger target length compromising on the quality of the wrap.

Learning Outcomes - Acquired knowledge of surface wrap on any geometry.

Result - Geometry was modified according to the given conditions and the proper surface wrap was generated.

Conclusion - A detailed report of the entire surface wrap process was mentioned.

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Bhavesh Kumbhare (15)

Heat Transfer analysis using Battery Thermal Management System (BTMS) for Lithium ion battery module used in Electronic Vehicles using Ansys Fluent

Problem Statement AIM - A simulation for heat transfer analysis for the cylindrical Lithium ion battery, with heat generation boundary condition, is to be performed using Ansys Fluent. INTRODUCTION -Electric vehicles charge their batteries with electricity rather than using fossil fuels such as gasoline or diesel. Electric…

19 Jun 2023 11:58 AM IST

Week 9 - Parametric study on Gate valve.

AIM -A steady-state simulation for the parametric study of flow through a gate valve is to be performed in Ansys Fluent.INTRODUCTION & THEORY - Gate Valve -The most common type of valve in water supply systems is a gate valve. It is a linear-motion isolation valve with the ability to stop or allow flow. The closure…

23 Jan 2023 02:22 PM IST

Week 3 - External flow simulation over an Ahmed body.

AIM -A simulation for external flow analysis over an Ahmed body is to be carried out for the velocity of 25 m/sec with the default air properties in Ansys fluent. INTRODUCTION - It is asked to compute an external flow simulation over an Ahmed body using air, with a 25 m/sec velocity, as working fluid. The geometry…

10 Jan 2023 09:00 AM IST

Week 6 - CHT Analysis on a Graphics card

AIM - A steady-state simulation for Conjugate Heat Transfer (CHT) analysis of Graphics Card to be performed using Ansys Fluent. INTRODUCTION - Conjugate Heat Transfer (CHT) is the exchange of thermal energy at the interfaces of solid and fluid domains to transfer heat. That is, it includes both conduction and convection…

06 Jan 2023 08:22 AM IST

Related Courses

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.