Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Week 2 Challenge : Surface meshing on a Pressure valve

QUESTION - For a pressure valve, check the geometrical errors, perform Topology cleanup and mesh the model with three different target lengths each individually. Also, include the concepts you learned. Target length = 1mm, 3mm & 5mmElement type = Tria ANSWER -Aim - To set the target length & mesh the given…

Bhavesh Kumbhare

updated on 24 Sep 2022

QUESTION -

For a pressure valve, check the geometrical errors, perform Topology cleanup and mesh the model with three different target lengths each individually. Also, include the concepts you learned.

Target length = 1mm, 3mm & 5mm

Element type = Tria

ANSWER -

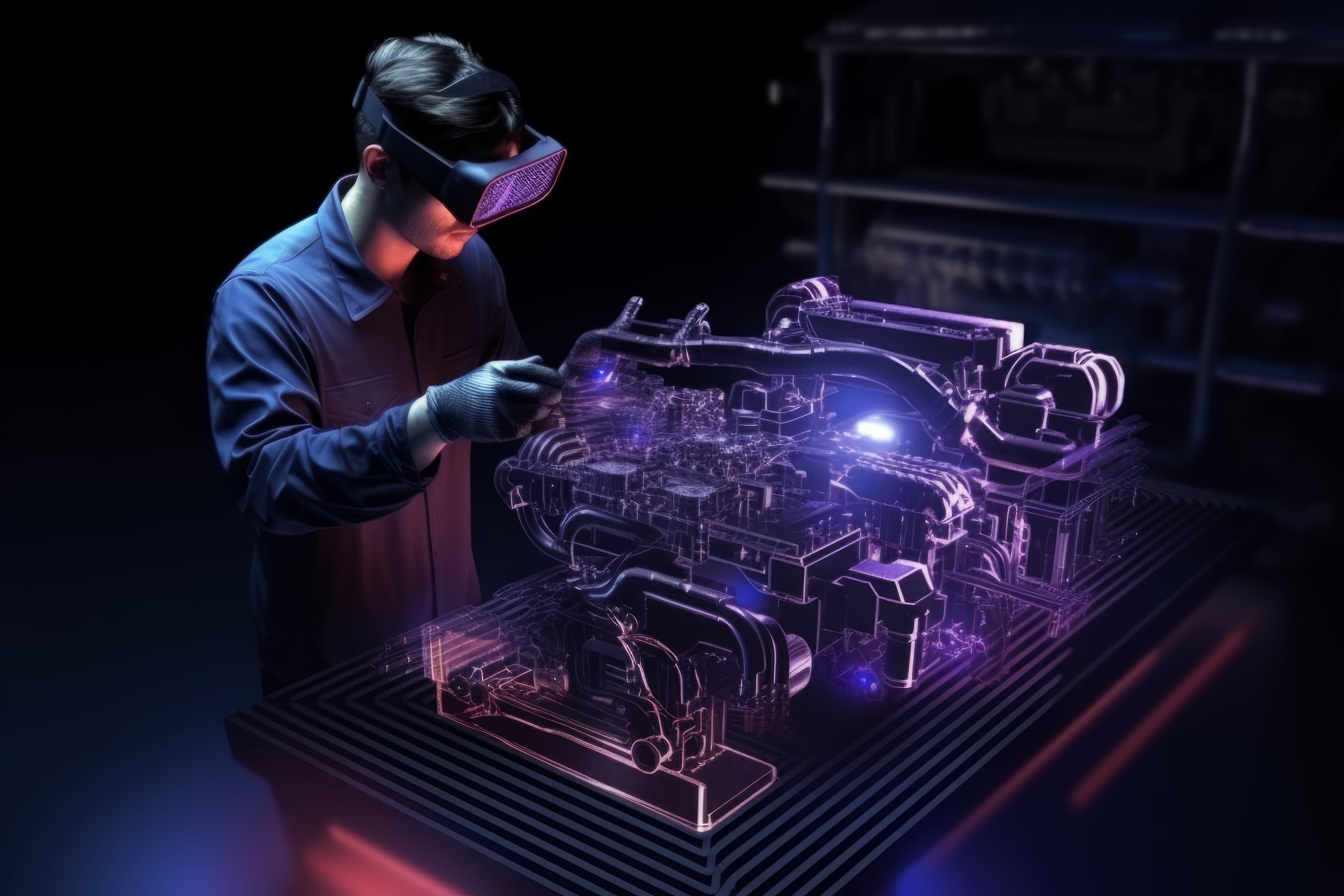

Aim - To set the target length & mesh the given model of pressure valve according to the conditions mentioned in the ANSA pre-processor. ANSA is a popular computer-aided engineering tool for CFD and Finite Element Analysis in the automobile sector.

A pressure valve is a kind of safety valve that is used to limit or control the pressure in a system. If pressure isn't controlled, it could build up and result in a process disruption, instrument, or equipment failure.

Procedure -

We will follow two major procedures to accomplish the task, viz.,

- Geometrical Errors Resolution and Topology Cleanup

- Mesh Generation

Here, the first procedure will be the same for all three models. However, each model will have a separate procedure for generating mesh.

Steps -

Import the Geometry. Turn the geometry to "Shadow display" mode from the "Wireframe display" mode so as to perform the desired operations on it.

- Geometrical Errors Resolution and Topology Cleanup

Here, we are working in "Topo Deck" by default.

Before proceeding toward meshing, we need to check for errors and clean the entire geometry.

Check all the errors in the given geometry:

Tool Bar > Checks Geometry > Geometry_Checks > Execute >

Here, you will find all the errors that your geometry contains.

Now, you will find several tools to resolve the geometrical errors under "Module Buttons Group"

Few Module Buttons which we use for this are,

CONS > Fill Hole

FACES > New > Existing Surface

FACES > New > Planar

FACES > New > Fitted

FACES > New > COONS

To correct various geometrical errors, various tools are implemented. The appropriate tool must be identified in order to reduce errors as much as possible.

Note - "Loop" Option under the "Status Bar" can be used to select a particular face rather than selecting each con one by one.

Here, we completed resolving all our geometrical errors shown in the previous geometry check.

Note - To make sure there are no errors still present, we must run a Geometry Check once more. Instead of errors, one may get certain warnings. Warnings are ignorable since they are generated by the geometry's shape, which is an inherent factor. However, depending on the geometry you are working with, every warning should not be ignored.

Now, in order to generate a good mesh, we need to assign properties to different components of the pressure valve. Generally, a pressure valve consists of Inlet, Outlet, Spring, Column, Column head & Body.

To assign these properties:

Tool Bar > PIDs > New > SHELL_PROPERTIES > Name > OK

One may change the color of each component assigned to a different color.

Here, I executed various boolean operations to assign the inlet and outlet first followed by the spring, column, and column head. The body was assigned at the last.

The PID which is not of any use can be deleted by using "Compress Tool" in the Tool Bar.

Here, we completed assigning PIDs to various components of our geometry.

Perform a geometry check to make sure our geometry is accurate before moving on to mesh generation. There are two penetration/intersection problems here, even though there are no geometry errors. By clicking our mouse over the errors, we can see what they are in detail. Between Column and Spring, there is a mistake in this case.

To resolve these errors we need to use "Intersect Tool" under Faces Module.

Face Module > Intersect > First > select the Column > middle click > Second > select the Spring > middle click

Now, we will be asked to 'Keep' or 'Delete' some particular highlighted faces one by one. Delete the faces which aren't necessary and keep the faces that are necessary for the geometry.

Once, again perform the geometry check and now all the errors have been resolved and we are ready to generate mesh over the geometry. Warnings may be ignored as mentioned earlier.

Now, save the file as we have to perform meshing three times with three individual target lengths.

- Mesh Generation

In order to generate a mesh with three different target lengths, that is, 1 mm, 2 mm & 3 mm, we need to perform meshing three individual times on the saved geometry file.

Click "Classic Mesh". To generate mesh, we need to follow three steps:

-

-

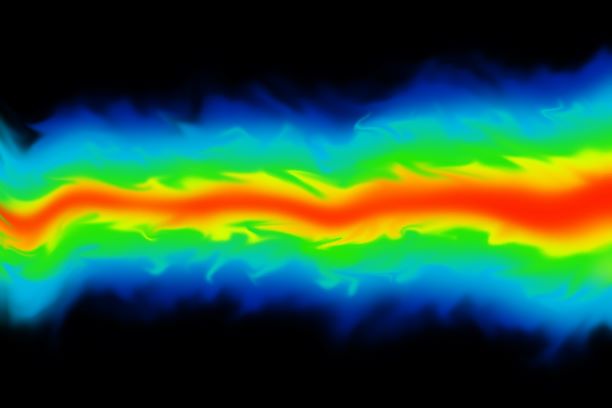

Click "Mesh Parameters" in the Toolbar. Under the "Basic" menu, select mesh type as "CFD Mesh" & element type as "Tria". Enter the minimum target length and maximum target length. Click OK. Here, we used CFD mesh instead of General mesh because the former gives more accurate results. One can select General mesh as well, there will be no error in the final results.

Sr. No. Target length provided Minimum Target length Maximum Target length 1) 1 mm 0.6 mm 1.4 mm 2) 3 mm 2.6 mm 3.4 mm 3) 5 mm 4.6 mm 5.4 mm - Perimeters Module > Spacing > Auto CFD > Perimeters > Select entire geometry > middle click > OK > Macros > Select entire geometry > middle click > OK

- Mesh Generation Module > CFD > Visible

-

Thus, Mesh is generated according to the given target lengths.

Learning Outcomes - Acquired knowledge of various new tools and how to use them to execute operations on given geometry.

Result - Geometry was modified according to given conditions and proper meshing was done.

Conclusion - A detailed report of the entire meshing process was mentioned.

As the spring appeared to be deformed and the mesh components generated over the geometry were highly unstructured, mesh with a 5 mm target length was geometry-inappropriate. A mesh with a 3 mm target length was marginally better, and the geometry of the elements appeared organized. The geometry of the spring appeared perfect in the final mesh, which had a 1 mm target length, and the overall mesh parts were structured.

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Bhavesh Kumbhare (15)

Heat Transfer analysis using Battery Thermal Management System (BTMS) for Lithium ion battery module used in Electronic Vehicles using Ansys Fluent

Problem Statement AIM - A simulation for heat transfer analysis for the cylindrical Lithium ion battery, with heat generation boundary condition, is to be performed using Ansys Fluent. INTRODUCTION -Electric vehicles charge their batteries with electricity rather than using fossil fuels such as gasoline or diesel. Electric…

19 Jun 2023 11:58 AM IST

Week 9 - Parametric study on Gate valve.

AIM -A steady-state simulation for the parametric study of flow through a gate valve is to be performed in Ansys Fluent.INTRODUCTION & THEORY - Gate Valve -The most common type of valve in water supply systems is a gate valve. It is a linear-motion isolation valve with the ability to stop or allow flow. The closure…

23 Jan 2023 02:22 PM IST

Week 3 - External flow simulation over an Ahmed body.

AIM -A simulation for external flow analysis over an Ahmed body is to be carried out for the velocity of 25 m/sec with the default air properties in Ansys fluent. INTRODUCTION - It is asked to compute an external flow simulation over an Ahmed body using air, with a 25 m/sec velocity, as working fluid. The geometry…

10 Jan 2023 09:00 AM IST

Week 6 - CHT Analysis on a Graphics card

AIM - A steady-state simulation for Conjugate Heat Transfer (CHT) analysis of Graphics Card to be performed using Ansys Fluent. INTRODUCTION - Conjugate Heat Transfer (CHT) is the exchange of thermal energy at the interfaces of solid and fluid domains to transfer heat. That is, it includes both conduction and convection…

06 Jan 2023 08:22 AM IST

Related Courses

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.