Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Week 14 challenge

AIM: The objective of this project is to design a butterfly valve and apply GD&T to it's components and final assembly using Siemens NX. INTRODUCTION A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The…

Raghav verma

updated on 23 May 2023

AIM: The objective of this project is to design a butterfly valve and apply GD&T to it's components and final assembly using Siemens NX.

- INTRODUCTION

A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a shaft. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow. There are different kinds of butterfly valves, each adapted for different pressures and different usage.

Hereafter modeling various components of the Butterfly valve, GD&T (Geometric Dimensioning & Tolerancing) is applied to each component and final assembly. Geometric Dimensioning and Tolerancing (GD&T) is a system for defining and communicating engineering tolerances. It uses symbolic language on engineering drawings and computer-generated three-dimensional solid models that explicitly describe nominal geometry and its allowable variation. It tells the manufacturing staff and machines what degree of accuracy and precision is needed on each controlled feature of the part. GD&T is used to define the nominal (theoretically perfect) geometry of parts and assemblies, to define the allowable variation in form and possible size of individual features, and to define the allowable variation between features.

There are several standards available worldwide that describe the symbols and define the rules used in GD&T. One such standard is the American Society of Mechanical Engineers (ASME) Y14.5. This article is based on that standard, but other standards, such as those from the International Organization for Standardization (ISO), may vary slightly. The Y14.5 standard has the advantage of providing a fairly complete set of standards for GD&T in one document. The ISO standards, in comparison, typically only address a single topic at a time.

- Advantages of applying GD&T:

- Saving Money - GD&T enhances design accuracy by allowing for appropriate tolerances that maximize production. For many projects, the process provides extra or bonus tolerances, further increasing cost-effectiveness.

- Offering Uniformity and Convenience - As a single, consistent language, GD&T reduces guesswork and interpretation while ensuring consistent geometries across design and manufacturing.

- Assisting Digital Design Methods — Clear, concise GD&T data is readily adaptable to digital design programs, including nearly universally used 2D and 3D CAD files.

- Ensuring Dimensional and Tolerance Requirements — By explicitly stating all design requirements, a thorough GD&T process guarantees accurate fulfillment of all dimensional and tolerance specifications.

- Providing Accurate Communication — Today’s intricate designs demand the most accurate and reliable communication. GD&T enables designers, manufacturers, and inspectors to communicate clearly with one other, saving time and making the process more efficient.

- Applications of Butterfly Valves

- A Butterfly valve can be used in many different fluid services and they perform well in slurry applications. The following are some typical applications of Butterfly valves:

- Cooling water, air, gases, fire protection, etc.

- Slurry and similar services

- Vacuum service

- High-pressure and high-temperature water and steam services

- Advantages of Butterfly Valves

- Compact design requires considerably less space, compared to other valves

- Light in weight

- Quick operation requires less time to open or close

- Available in very large sizes

- Low-pressure drop and high-pressure recovery

- Disadvantages of Butterfly Valves

- Throttling service is limited to low differential pressure

- Cavitation and choked flow are two potential concerns

- Disc movement is unguided and affected by flow turbulence

- PARTS OF BUTTERFLY VALVE BODY:

- Body

The body of the butterfly valve is the part that fits between the two pipes. This slim valve comes in two major body styles: wafer and lug. The wafer style body is the most economical of the two. It is connected to the pipes with bolt holes that run through the body of the valve. This design is easy to install and primarily used to prevent backflow in universal flow systems. However, it should be noted that they are not recommended for use in systems that require regulation.

Lug style butterfly valves are slightly more expensive than their counterpart but offer a few distinct advantages. Lug butterfly valves are connected to the pipe through protruding lug holes on the outside of the body of the valve. With this design, the valve actually helps carry the weight of the piping throughout its body, unlike the wafer valve. This allows for removing piping from one side of the valve for dead-end servicing.

Disk

Both wafer and lug style butterfly valves have a disk inside, and this disk is what controls the flow of media through the valve, much like a gate in a gate valve or the ball in a ball valve.

The disc of the valve can be either concentric or eccentric. The simplest of these two is the concentric disk. In the concentric design the stem passes through the centerline of the disk. Concentric valves are commonly used in low pressure applications.

The eccentric disk design, however, has a stem that doesn’t pass through the center line, but rather behind it, in the opposite direction of the flow. The eccentric disk was first designed to help prevent contact of the disk and seal before it was fully closed to help prolong and improve life of the valve.

3. Stem

The stem of the butterfly valve may seem like a small part, but it plays an important role. The stem is what connects the disk inside to the handle outside. Without it, the valve would not be able to open or close, and what’s a valve if it can’t open or close?

The stem has two different designs—wetted or non-wetted—which refers to the protection on the stem. Non-wetted stems are protected against any potential corrosive or erosive media in the line. Wetted stems are not protected against these and, thus, must be made of material that is compatible to the media flowing through the line.

4. Seat

The seat of a butterfly valve is made of different elastomers or polymers and is either bonded to the body or pressed or locked down. The seat runs along the inner diameter of the valve. When the disk presses along the seat, they seal together to stop the flow. When butterfly valves were first designed the metal of the disk sat against the metal body, which did not provide a tight, leak-free seal. The addition of elastomers or polymers to the design of the valve is what helps provide the leak-proof seal.

Manual Actuation vs. Automatic Actuation

One major advantage of butterfly valves is that they can be operated either manually or automatically to fully rotate the disc inside the valve.

Manual actuation for butterfly valves involves either a hand lever or gears. Hand levers are used primarily on smaller valves, and much like their name implies, are a lever on top that is rotated up to 90 degrees to open, close, or regulate flow.

Gear operated valves are used on bigger valves and utilize a gearbox to help open and close the valve. While the gearbox does make it easier on the operator to open the valve, it does come at the price of a decreased speed.

The ability of butterfly valves to be operated automatically allows them to be controlled remotely. Automatic actuation occurs by use of either an electric motor, hydraulic pressure, or by pneumatic pressure.

Automatic butterfly valves are extremely helpful with larger valves (butterfly valves have been produced as large as 200inches!), and come with fail safe options like fail-open (open in case of failure) or fail-close (close in case of failure).

DESIGNED PROJECT DETAILS:

1. VALVE BODY:

APPLIED GD&T DRAWING:

2. SHAFT/ STEM:

GD&T APPLIED DRAWING:

3. DISC PLATE:

GD&T APPLIED DRAWING:

4. LEVER

GD&T APPLIED DRAWING:

5. RETAINER PLATE :

GD&T APPLIED DRAWING:

6. NUT & SCREWS:

GD&T APPLIED DRAWING:

FINAL ASSEMBLY:

GD&T APPLIED DRAWING:

CONCLUSION:

I have applied GD&T with all the necessary details as per industry standards following ASME Y14.5.

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Raghav verma (23)

Project - Analysis of a practical automotive wiring circuit

1. Identification of Major Elements in the DiagramNo. Element1 Battery2 Starter3 Generator4 Current and Voltage Regulator5 Ignition Switch (IGN. SW.)6 Distributor7 Ignition Coil8 Breaker9 Headlamps (Scaled Beam)10 Parking Lamp11 Horn12 Foot Selector Switch13 Ammeter14 Dome Light and Switch15 Tail and Stop Lights16 Fuel…

07 May 2025 05:55 AM IST

Week 2:- BiW Fixture Basics Challenge

1. Process of Project Execution Activity: Project execution involves the implementation of project plans and the completion of project deliverables. Here's a general outline of the process: - Initiation: Start the project by defining objectives, scope, and resources. - Planning: Develop…

25 Mar 2024 02:16 PM IST

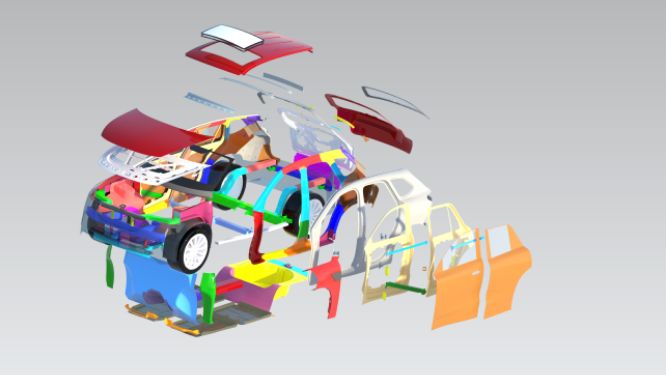

Week 1:- Introduction to BiW and Fixtures Challenge

BIW (Body in White): BIW, short for Body in White, refers to the stage in automotive manufacturing where a car body's sheet metal components have been welded together but before the final components, such as the engine, chassis, interior, and trim, have been added. It represents the skeleton of the vehicle and serves…

25 Mar 2024 02:03 PM IST

Week 14 challenge

AIM: The objective of this project is to design a butterfly valve and apply GD&T to it's components and final assembly using Siemens NX. INTRODUCTION A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The…

23 May 2023 01:37 PM IST

Related Courses

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.