Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Week 1:- Introduction to BiW and Fixtures Challenge

BIW (Body in White): BIW, short for Body in White, refers to the stage in automotive manufacturing where a car body's sheet metal components have been welded together but before the final components, such as the engine, chassis, interior, and trim, have been added. It represents the skeleton of the vehicle and serves…

Raghav verma

updated on 25 Mar 2024

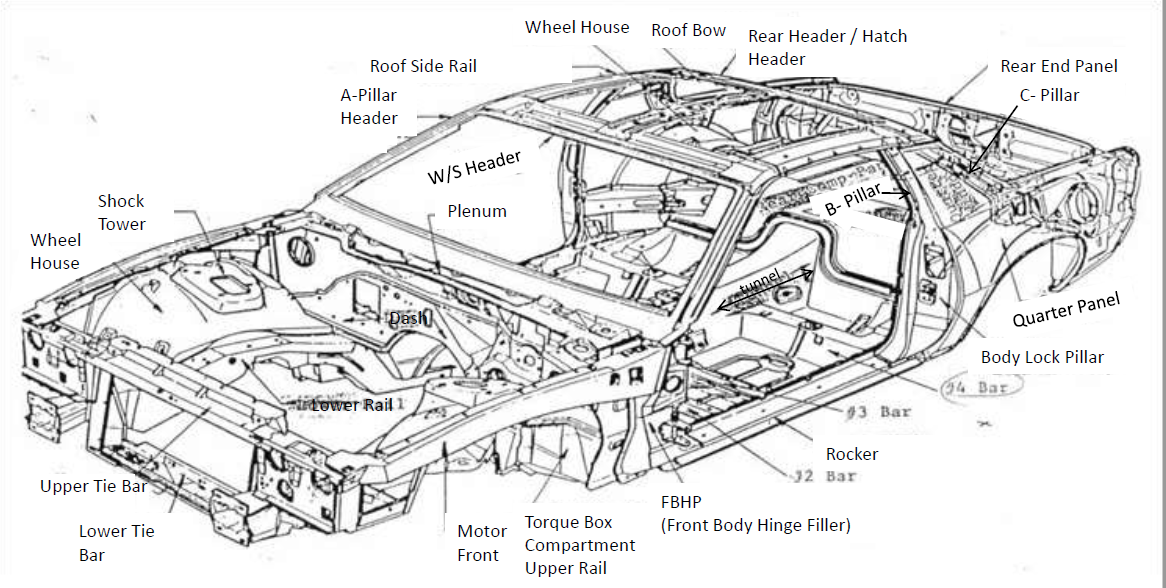

BIW (Body in White):

BIW, short for Body in White, refers to the stage in automotive manufacturing where a car body's sheet metal components have been welded together but before the final components, such as the engine, chassis, interior, and trim, have been added. It represents the skeleton of the vehicle and serves as the foundation for the assembly of other components. BIW typically consists of several parts, each serving a specific purpose in the overall structure of the vehicle.

Parts of a BIW:

1. Body Side Outer (BSO): This is the outer panel of the car body, including the doors, roof, and side panels.

2. Body Side Inner (BSI): The inner panel of the car body, providing structural support and housing for components such as wiring and insulation.

3. Underbody: This component forms the lower part of the car body, including the floor pan and other structural elements underneath the vehicle.

4. Front End: The front portion of the car body, including the hood, fenders, and front bumper.

5. Rear End: The rear portion of the car body, including the trunk, rear quarter panels, and rear bumper.

BIW Nomenclature:

BIW nomenclature refers to the systematic naming or labeling of the various components and parts of a Body in White structure. This naming convention helps in accurately identifying and referencing different parts during the design, manufacturing, and assembly processes. It ensures clarity and consistency in communication among engineers, designers, and manufacturers involved in BIW production.

Fixture and its Types:

A fixture is a device used to securely hold and position a workpiece during manufacturing, machining, or assembly processes. It ensures accuracy, repeatability, and stability of the workpiece, enabling precise and efficient production. There are several types of fixtures, including:

1. Machining Fixture: Used in machining operations such as milling, drilling, and grinding to hold the workpiece securely in place and provide access to specific areas for machining.

2. Welding Fixture: Designed to accurately position and hold components in place during welding processes, ensuring proper alignment and dimensional accuracy of welded joints.

3. Assembly Fixture: Used in assembly processes to align and hold multiple components together during assembly, facilitating efficient and error-free assembly of complex products.

4. Inspection Fixture: Utilized for quality control purposes to precisely position and hold workpieces during inspection processes, allowing accurate measurement and evaluation of dimensional accuracy and quality.

Basic Principle of Fixture Design:

The basic principle of fixture design revolves around ensuring the following key aspects:

1. Accuracy: The fixture must accurately position and hold the workpiece in the desired orientation to meet dimensional tolerances and quality requirements.

2. Stability: It should provide sufficient rigidity and stability to withstand machining or assembly forces without deflecting or deforming, maintaining dimensional integrity.

3. Accessibility: The fixture should allow easy access to the workpiece for machining, assembly, or inspection operations without obstruction.

4. Repeatability: It should enable consistent and repeatable positioning of the workpiece to achieve uniformity in production output.

5. Ease of Use: The fixture design should be user-friendly, allowing quick and efficient setup and adjustment for different workpieces or manufacturing processes.

Types of BIW Stations:

BIW stations are specific areas or stages in the automotive manufacturing process where various operations are performed on the Body in White structure. The types of BIW stations include:

1. Welding Station: Where welding operations are performed to join individual sheet metal components together to form the car body structure.

2. Assembly Station: Where additional components such as doors, hoods, fenders, and other body panels are assembled onto the BIW structure.

3. Inspection Station: Where the completed BIW structure undergoes inspection and quality control checks to ensure dimensional accuracy, weld integrity, and overall quality.

4. Surface Treatment Station: Where surface treatments such as painting, coating, or corrosion protection are applied to the BIW structure to enhance its appearance and durability.

5. Final Assembly Station: Where the completed BIW structure is integrated with other vehicle components such as the chassis, engine, interior, and trim to form the final assembled vehicle ready for testing and delivery.

Basic Terminologies used in BIW Fixture:

1. Locating Pins: These are precision pins used to accurately position the workpiece within the fixture.

2. Clamps: Devices used to securely hold the workpiece in place within the fixture during machining, welding, or assembly operations.

3. Datum Surfaces: Flat or feature surfaces on the workpiece used as reference points for positioning and alignment within the fixture.

4. Toggle Clamps: Clamping mechanisms that provide quick and secure locking of the workpiece in place within the fixture.

5. Fixture Base Plate: The foundation or platform of the fixture on which the workpiece is mounted and secured during machining or assembly processes.

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Raghav verma (23)

Project - Analysis of a practical automotive wiring circuit

1. Identification of Major Elements in the DiagramNo. Element1 Battery2 Starter3 Generator4 Current and Voltage Regulator5 Ignition Switch (IGN. SW.)6 Distributor7 Ignition Coil8 Breaker9 Headlamps (Scaled Beam)10 Parking Lamp11 Horn12 Foot Selector Switch13 Ammeter14 Dome Light and Switch15 Tail and Stop Lights16 Fuel…

07 May 2025 05:55 AM IST

Week 2:- BiW Fixture Basics Challenge

1. Process of Project Execution Activity: Project execution involves the implementation of project plans and the completion of project deliverables. Here's a general outline of the process: - Initiation: Start the project by defining objectives, scope, and resources. - Planning: Develop…

25 Mar 2024 02:16 PM IST

Week 1:- Introduction to BiW and Fixtures Challenge

BIW (Body in White): BIW, short for Body in White, refers to the stage in automotive manufacturing where a car body's sheet metal components have been welded together but before the final components, such as the engine, chassis, interior, and trim, have been added. It represents the skeleton of the vehicle and serves…

25 Mar 2024 02:03 PM IST

Week 14 challenge

AIM: The objective of this project is to design a butterfly valve and apply GD&T to it's components and final assembly using Siemens NX. INTRODUCTION A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The…

23 May 2023 01:37 PM IST

Related Courses

0 Hours of Content

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.