Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Photo Realistic Rendering

MODELLING AND RENDERING OF AMERICAN CHOPPER INTRODUCTION: SolidWorks is a solid modeling computer-aided design and computer-aided engineering application. It helps the designers quickly sketch out ideas, experiment with features and dimensions, and producemodels and detailed drawings.This project focus on the modelling…

Ahamed Sukriya

updated on 14 Apr 2022

MODELLING AND RENDERING OF AMERICAN CHOPPER

INTRODUCTION:

SolidWorks is a solid modeling computer-aided design and computer-aided engineering application.

It helps the designers quickly sketch out ideas, experiment with features and dimensions, and produce

models and detailed drawings.This project focus on the modelling and rendering of American chopper.

OBJECTIVE:

To create chopper by using different features and sketching techniques.The major steps required are-

STEPS REQUIRED FOR THE DESIGN:

- Open a new file

- Selection of new plane

- Sketch as per dimension

- Surface modelling or solid modelling

- Applying required commands

- Save the model

MODELLING:

THE AMERICAN CHOPPER CONSISTS OF THE FOLLOWING PARTS

- Chassis

- Engine

- Front fork

- Pedal

- Chain

- Oil tank

- Gas tank

- Transmission belt

- Front fender

- Rear fender

- Front wheel

- Rear wheel

- Kick stand

WEEK 1:

PARTS: 1.Transmission belt 2.Kick stand 3.Front fender

Commands used:

- Lines and circles

- Extrude boss

- Lofted boss

- Dome

- Fillet

- Extrude cut

- Split body

- Revolve boss

1.TRANSMISSION BELT

_1649919031.png)

2.KICK STAND

_1649919358.png)

3.FRONT FENDER

_1649919153.png)

The above mentioned commands are used to design the week 1 parts for the chopper and the dimensions and instructions

are followed as per the week 1 video.Most of the solid modelling tools are used to design the above parts.

WEEK 2:

PARTS: 4.Oil tank 5.Chain 6.Pedal

Commands used:

- Sweep

- Revolve boss

- Splines

- Trim

- Extrude cut

- Extrude boss

- Shell

- Fillet

- Pattern types

- Split body

- Combine

4.OIL TANK

_1649919203.png)

5.CHAIN

_1649919241.png)

6.PEDAL

_1649919308.png)

In the oil tank there are two solid bodies created and are combined to a sigle body by using combine feature.Then fillets are

are added and shell to give inner spacing.To create the chain two chain links are saved for easy operation dimension as per

the week 2 video.The above following commands are used to design to make the week 2 parts.The dimensions and intructions

are followed as per the week 2 video.

WEEK 3:

PARTS: 7.Front wheel

Commands used:

- Sweep

- Revolve cut

- Circular pattern

- Combine

- Extrude cut

- Revolve boss

- Chamfer

- Fillet

7.FRONT WHEEL

_1649919409.png)

In front wheel we are using the circular pattern for making spider web design for the rim.Revolve cut is also used on the rim

for better surface finish.The above following commands are used to design the week 3 parts and the dimensions and instruction

are followed as per week 3 video.

WEEK 4:

PART: 8.Rear wheel 9.Front fork

Commands used:

- Sweep

- Revolve boss

- Mirror pattern

- Dome

- Projected curve

- Combine

- Chamfer

- Extrude boss

- Fillet

8.REAR WHEEL

_1649919568.png)

9.FRONT FORK

_1649919615.png)

The rear wheel similar to the front wheel apart from the size. Here the front wheel chain sprocket is the additional part used. The usage

of projected curve and sweep is given for a better finish on the handle of the front fork. Mirror pattern is also used to complete the

other side .The above following commands are used to design to make the week 4 parts and the dimensions and instructions are

followed as per the week 4 video.

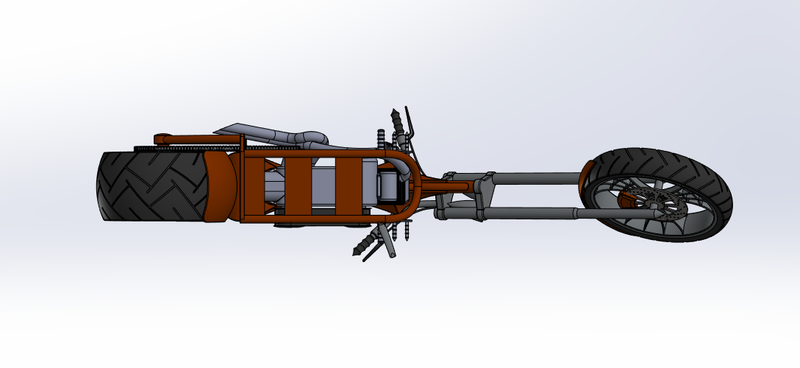

WEEK 5:

PARTS: 10.Chassis 11.Engine

Commands used:

- Sweep

- Revolve

- Extrude

- Dome

- Projected curve

- Split

- Mirror

10.CHASSIS

_1649919666.png)

11.ENGINE

_1649919711.png)

In the chassis model sweep and projected curves are used for the surface modelling to give a better finish.We also use the blue print

of the chopper to get a better view of the chassis.The projected curves are used to make the engine exhaust, most of the solid modelling

features are used to finish the engine.The above mentioned commands are used to design the week 5 parts and the dimensions and instructions

are followed as per the week 5 video.

WEEK 6:

PARTS: 12.Gas tank

Commands used:

- Surface loft

- Surface Sweep

- Boundary surface

- Revolve boss

- Extrude cut

- Knit surface

- Projected curve

- Split

- Cut sweep

- Fillet

- Surface trim

12.GAS TANK

_1649919761.png)

In the gas tank both solid and surface modelling tools are used for better finish.The above following commands are used to design the week 6 parts

and the dimensions and instructions are followed as per the week 6 video.

Once the parts are done ,material for each part are given by appearance option in solidworks. Material selction gives the parts more realistic outlook

of the product.

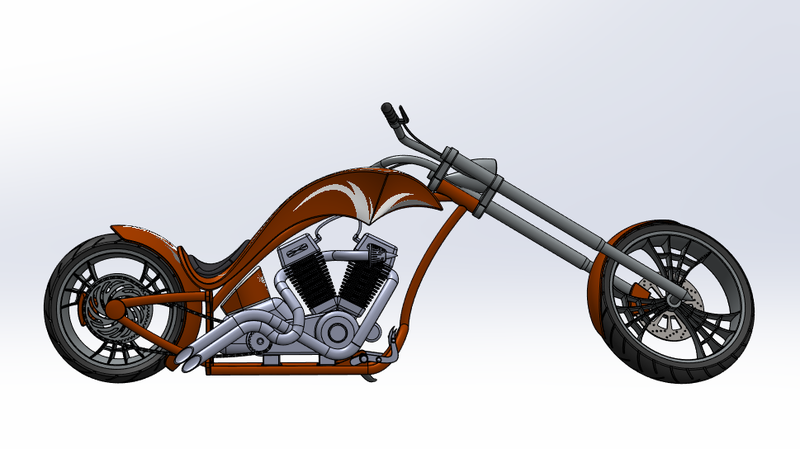

ASSEMBLY OF AMERICAN CHOPPER:

To make the assembly of American chopper we use mates

- Concentric mate

- Parallel mate

- Angle mate

- Distance mate

- Advanced mate

ISOMETRIC VIEW OF ASSEMBLY

FRONT VIEW OF ASSEMBLY

SIDE VIEW OF ASSEMBLY

TOP VIEW OF ASSEMBLY

REAR VIEW OF ASSEMBLY

BOTTOM VIEW OF ASSEMBLY

PHOTOVIEW360 RENDERING

To make the chopper more realistic we use the PHOTOVIEW360.

Commands used:

- Camera

- Decals

- Edit scene

- Light

ISOMETRIC VIEW

FRONT VIEW

SIDE VIEW

REAR VIEW

CONCLUSION:

Modelling,assembly and rendering of an American chopper is successfully done by SOLIDWORKS.

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Ahamed Sukriya (29)

Week 11 - Final project

DEVELOPMENT OF A DOOR TRIM PANEL Q -Creation of CAD model considering following inputs as like in OEM and tier1 companies a) Class A surface b) Nominal thickness : Refer master sections c) Attachment strategy Find a attachment strategy for the door panel complete work. Use Push pin with Dog house for Lower…

09 Dec 2022 02:47 PM IST

Project 1

ENGINE WIRING HARNESS USING CATIA V5 Statement of assignment: Route the Wiring harness on Given Engine and Prepare flatten view drawing in CATIA V5. Application of all Packaging rules, Industry best practices studied in this course shall be demonstrated in design. Apply Protection coverings as required. Available connector…

07 Dec 2022 09:12 PM IST

Project 2

AUTOMOTIVE WIRING HARNESS BACKDOOR Statement of assignment: Route the Wiring harness on Given car body and Prepare flatten view drawing in CATIA V5. Application of all Packaging rules, Industry best practices studied in this course shall be demonstrated in design. Apply Protection coverings as required. Available connector…

07 Dec 2022 10:25 AM IST

Wiring harness design in CATIA V5 - 3D modeling Week 5 & 6 Challenge

Wiring harness design in CATIA V5 Aim- Q1. Route the following harness layout in Electrical workbench. Make assumption for harness bundle diameters. Use the connectors provided. After completion of routing, Check the bundle Continuity. Add snap of result in submission Add annotation to all connectors. Make an assumptions…

24 Nov 2022 03:16 PM IST

Related Courses

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.