Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Hood design-Week 2

Hood Design Objective: The main objective of the project is to design hood BIW that satisfies the manufacturing requirements functional requirements as well as Euro NCAP standards. Hood The hood is the hinged cover over the engine of motor vehicles. Hoods can open to allow access to the engine compartment for maintenance…

D Vinay Kumar

updated on 08 Jul 2022

Hood Design

Objective: The main objective of the project is to design hood BIW that satisfies the manufacturing requirements functional requirements as well as Euro NCAP standards.

Hood

The hood is the hinged cover over the engine of motor vehicles. Hoods can open to allow access to the engine compartment for maintenance and repair. In generally for passenger cars the hood may be held down by a concealed latch, but in race cars or cars with after market hoods the hood may be held down by hood pins. Hoods are typically made out of steel or aluminum.

Parts of Hood

- Hood outer panel

- Hood inner panel

- Hinge and its reinforcements

- Striker and its reinforcements

Hoot outer panel is the styling metal cover over the inner hood panel which provides strength for the hood. The outer hood and inner hood are attached using sealants in between and hemming operation is performed on the outer panel to hold the inner panel. Stiffener pads is given between inner hood and outer hood to avoid rattling at high speeds. Hinge is attached for the hood inner panel to give the rotation0 for the hood. Striker is used to lock the hood in closed position. Generally, the hinge and striker losses its strength after mating with hood, so reinforcements are given for strength.

Parameters to be considered for design of hood:

- Opening angle

- Material selection

- Support rod

- Hinge position

- Striker position

- Pedestrian safety

- Opening angle

Opening angle is one of the important parameters taken for consideration while designing the hood. Opening angle of the hood differs from country to country based on the average height of the person to avoid the head impact or injury.

2.Material Selection

Automotive industries expect to pass a number of significant properties like high tensile strength and high stiffens bending. So, material selection is the important part of design consideration. It must also provide good quality and safety to car body and occupants against crashes. It should also be able to protect from Noise, Vibration and Harshness. So as per the various considerations only steel and aluminum has been preferred for hood design.

- Support rod

There are two types of support rods are being used to hold the car hood.

- Support rod

- Gas stay

Support rod is long cylindrical rod used to lift the hood manually. One end is connected to the engine compartment and other end is hooked to the inner mounting of the hood in open condition, during the closed condition the support rod is disconnected from the mount and placed on the support provided to hold the support rod to restrict the moment. Generally, the support rod is placed on the left side of the hood to avoid the difficulty in replacing the battery. Small bends are given to the support rod to improve strength.

- Gas stay

Gas stay is a rod and cylinder arrangement that operates due to the force excreted by the compressed air stored inside the cylinder. Luxury car makers provide gas stay to lift the hood and hold it in place. It takes minimal efforts to lift heavy hood and lends that upper market feel to the car. Gas stay needs extra supports to hood and engine compartment and is heavier than support rod.

3.Hinge

The hood hinge is used to join the car body and the hood and also acts as bracket mechanism to open and close the hood. Every car has two hinges installed. The hinges to be fixed on the flat surface of the hood improper fixing of hinges leads to loosening of fasteners and resulting in NVH issues.

4. Striker position

The striker to be positioned always perpendicular to the trajectory of the hood and the surface where the striker to be mounted on the inner panel must be flat in order to avoid NVH issues.

6. Pedestrian safety

Road transport remains the most favored mode of transport for both freight and passenger moment. Due to steadily increasing Euro NCAP developed the test procedures for active pedestrian protection systems of passive vehicle safety. It has created the five-star rating system determined from a series of tests. The testes are conducted in a simplified, important real-life scenarios that could result in injury or kill car occupants. The star rating reflects how well the car performs. The higher star show the car is did good in all the tests. According to Euro NCAP for pedestrian protection it defines the various zones on hood and tested for crash analysis.

When the car hits or crashes the pedestrian, The whole human body is get contact with front of car. At this moment the impact will be more on the pedestrian head than other parts because of hood position so the distance taken from the head impact area to the ground is referred as wrap around distance.

The crash test analysis Euro NCAP determines the two tests on head impact based on wrap around distance. One id child head impact zone and other is adult head impact zone test. After the test analysis it says that the child head is mostly impacted in between 1000 and 1700 mm WAP and adult head is impacted in between 1700 to 2100 mm WAD

Mastic Data

Mastic is the sealant applied between hood outer panel and inner panel. The main purpose of adding the sealant is to avoid NVH issues as well as providing good aesthetic looks to the outer panel. As the assemble of inner panel and outer panel are subjected to welding process, it may result in some spots on outer panel. Also, by direct joining of outer panel leads to generate sound when vehicle is in motion. So, in order to overcome these issues, the sealant is provided between the gap of outer and inner panel. Initially it is in the form of glue but after treatment in hot furnace it gets hardened and provides strength between panels. Each sport of mastic sealant can cover and give a strength up to 80 mm diameter.

Sheet metal operations involved in design of HOOD

- Blanking and piercing

- Deep drawing

- Embossing

- Hemming

Blanking and Piercing

Blanking and piercing are shearing process in which a punch and die are used to produce parts from coil or sheet stock. Blanking produces the outside features of the component, while piercing produces internal holes or shapes. These two operations performed on the same work part simultaneously called as pierce and blank.

Deep drawing

Deep drawing is a sheet metal forming process by which the sheet metal is slightly clamped along its perimeter by a blank holder and radially drawn into a forming die by use of a punch. It can shape a sheet metal blank into a hollow body open one side or of a projected hollow body to one of the smaller cross sections without modifying its wall thickness

Embossing

Embossing is a forming operation in which indentations are made on the sheet such as strengthening ribs or raised letters. During the operation sheet metal is drawn into a shallow depth using with male and female match dies.

Hemming

Hemming is a sheet metal forming process in which sheets are joined by bending it usually to 180°. Automotive body panels and automotive parts such as deck-lids, trunk-lids, doors, hoods, and tailgates are formed by hemming process.

The accuracy of the hemming operation is very important since it affects the appearance of the surface and surface quality. Material deformations, which occur during the hemming process, can lead to dimensional variations and other defects in parts. Typical hemming defects are splits or wrinkles in the flange, material overlaps in the corner areas or material roll-in. This is why it is important to use simulation tools in order to, on the one hand, better understand the hemming process and, on the other hand, significantly reduce the number of “trial and error” loops during tryout und production.

There are various types of hemming operations:

- Conventional die hemming

- Roll hemming

In conventional die hemming, the flange is folded over the entire length with a hemming tool.

In roll hemming, the hemming roller is guided by an industrial robot to form the flange.

Design

Master section

Hood Outer panel

Hood Inner Panel

Inner hood is designed by considered the Euro NCAP standards. Mastic points are considered where it gives strength upto 80mm dia and placed accordingly to achieve maximum strength to the hood.

Emboss are created in such a way to distribute the impact towards the edges.

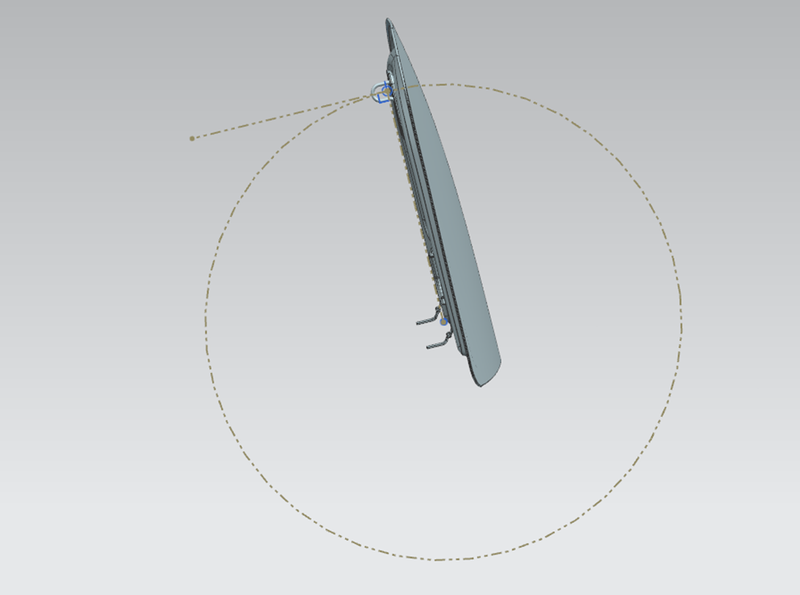

Hood opening and closing trajectory

For proper psotioning of striker on the hood, we need to create an axis from the hinge assembly. we have to posotion the hinges and extract the axis. A point is placed on the center of the axis and draw a circle. To check the correct position of the striker it has to be tangent to the circle.

Striker and Hinge

Striker and Hinge reinforcements

Reinforcements are created with thickness of 1.5 mm

Final assembly

Draft analysis

Conclusion

Design of the parts and assembly of hood is completed as per the manufacturing requirement, The inner panel was checked for its manufacturing feasibilty using draft analysis.

The latch and striker positions were studied and necessary reinforcements are developed for the inner panel.

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by D Vinay Kumar (28)

Project - Analysis of a practical automotive wiring circuit

1. Identify each of the major elements in the above automotive wiring diagram. The Major elements in the above wiring diagram ar Battery Generator Distributor Ammeter Fuse Ground/Earth Indicating Light/Beam light Starter Breaker Horn Light Switch/Selector Switch Junction Block Explain the Purpose and working of any…

12 Mar 2023 12:54 PM IST

Week 14 challenge

OBJECTIVE: The main objective of this project is to understand the fundamentals of GD&T and apply them to the design of a butterfly valve using Siemens NX. METHODOLOGY: For…

06 Nov 2022 08:06 AM IST

Project 2

Objective: To route the Wiring harness on Given car body and Prepare flatten view drawing in CATIA V5 by applying all the packing rules add the protrction covering. Packaging rules and assumptions made in this project: Avoid harness routing and clipping in a blind zone. Avoid harness routing through the small structural…

14 Oct 2022 04:13 PM IST

Project 1

Aim : TO route the wiring haress on given Engine and prepare Flatten view drawing by applying all packaging rules and protection covering as required Introduction: The automotive wiring harness consists of an electrical harness and the mechanical harness in the design. The current project is focused on the mechanical…

11 Oct 2022 04:27 PM IST

Related Courses

0 Hours of Content

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.