Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Week - 5 - 2D meshing for Plastic components

OBJECTIVES: To extract the midsurface & mesh the bottle cap component with given quality criteria. CAD MODEL IMAGE: …

MD SUBHAN

updated on 29 Mar 2023

OBJECTIVES: To extract the midsurface & mesh the bottle cap component with given quality criteria.

CAD MODEL IMAGE:

_1680089645.png)

PROCEDURE:

First import the CAD Model in ANSA Software or interface, then initial perform Topo after perform Topo Geometry checkup in this procedure we need to check for the following Geometrical errors present in the model like crack, overlap face, needle face, triple con, unchecked faces etc.

1. DO THE TOPO: To connect the Geometry each other.

_1680091489.png)

2. GEOMETRY CHECKUP: To check the Geometry cleanup.

_1680092982.png)

After the checkup fixing the errors if any, we can achieve this either by Manually or Autofix, hence all the CAD models were check for clean geometry and all their surface imperfections are fixed in the geometry check. after this procedure, geometry is free from error as we can see in below image.

_1680093531.png)

3. MIDSURFACE GENERATION:

Midsurface here taken by manual operation instead of Automid.

With the use of offset option midsurface is generated in the area having same thickness value.

_1680094275.png)

In this model we have trapezoidal surface where offset method will not work so we can use different method to generate midsurface.

_1680095327.png)

_1680095519.png)

_1680095783.png)

_1680096180.png)

So, for these areas we have to generate the curve at the middle by selecting both side cons.

Then those curve will be projected to surface & midsurface will be generated by using faces- new option.

We gave some ribs features, for which faces-middle option is used for midsurface generation.

INNER FEATURES:

_1680097502.png)

_1680098604.png)

TEETH:

_1680099319.png)

_1680099483.png)

Assign PID: After generating the midsurface for all the region, a new PID is to be assign for the midsurface.

_1680099701.png)

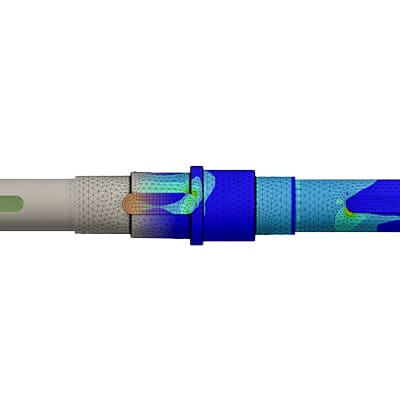

4. MESH GENERATION:

Before generating mesh, mesh parameter & quality parameter need to be set.

_1680101664.png)

_1680100883.png)

Now select Best mesh from mesh generation menu & select the area.

_1680101044.png)

One should use smooth option after mesh generation & even after reconstruct option for better mesh flow.

Use split, swap, paste command to reduce the trias and good mesh flow.

_1680101907.png)

Now select draw shell as solid from Quality Presentation parameters.

_1680102262.png)

5. FINAL MODEL:

_1680102649.png)

6. RESULTS:

1. Generation of misdurface for plastic model having varying thickness .

2. Commands like curve generation & project cons faces middle options etc.

3. Plastic Model is meshed with given quality criteria by assigning thickness value to various region.

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by MD SUBHAN (22)

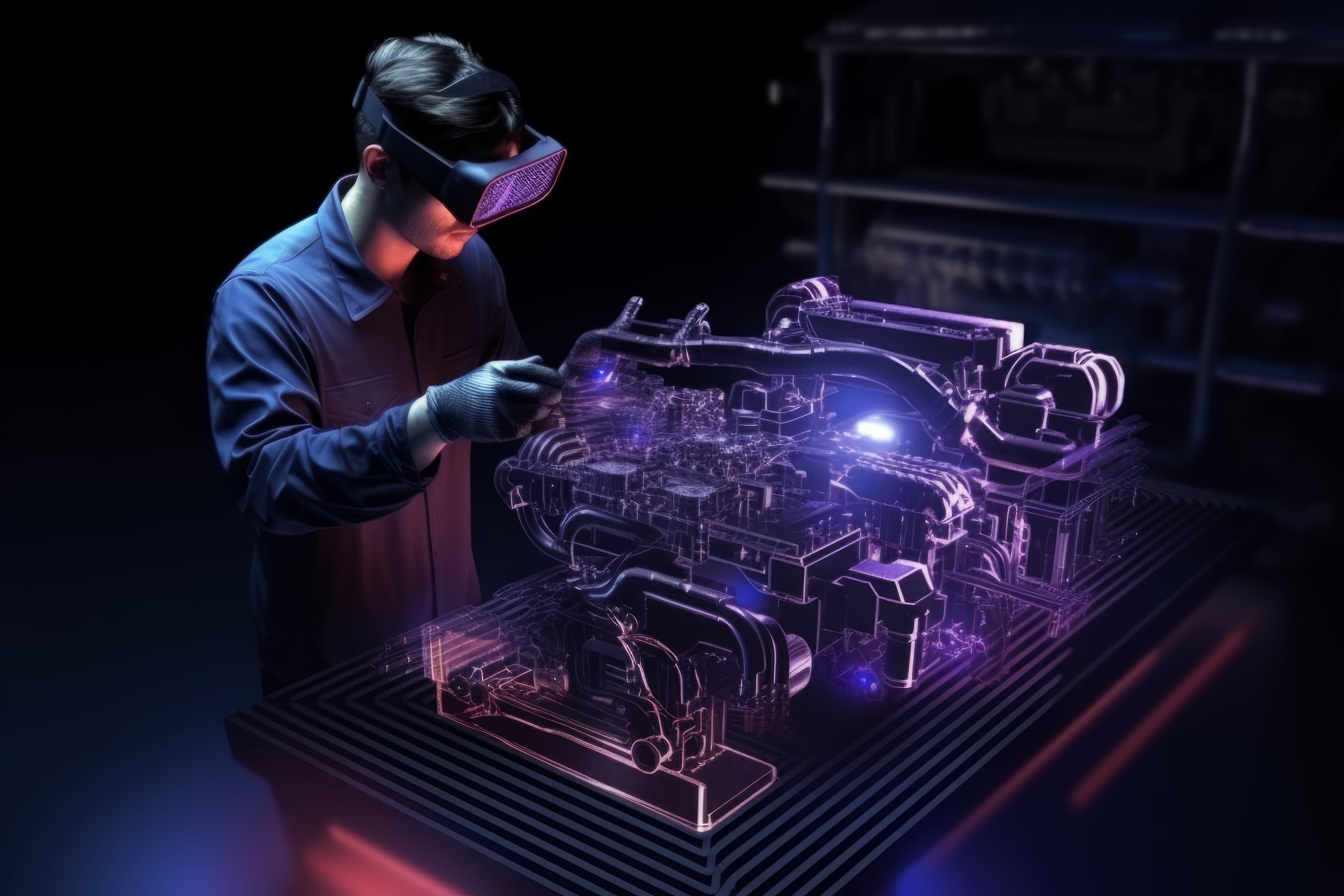

Assignment 7-Side Pole Crash Simulation Challenge

AIM: To perform the crash on the Side body of the car to a pole and analysis where stresses are working on it. OBJECTIVES:Side Body-BIW1. Checking the unit system and either following [Mg mm s] or [Kg mm ms].2. Creating appropriate interface, friction 0.2 and recommended parameters.3. There should be no penetrations…

07 Jul 2023 03:29 PM IST

Assignment 6-Frontal Crash Simulation Challenge

Frontal Crash test AIM: Frontal car crash simulation of Dodge Neon BIW using RADIOSS solver and Preprocessing using HyperMesh / HyperCrash. OBJECTIVE: The following are the requirements for this project: Set the model of the Neon Dodge ie, the FEA model, so that the required output requests can be post-processed from it. …

02 Jul 2023 07:48 PM IST

Assignment 5-RADIOSS Interfaces & Study of Effect of Notches Challenge

AIM: To study the RADIOSS Interfaces and the effect of notches using Hypermesh, Hyperview and Hypergraph 2D. OBJECTIVES OF THE PROJECT: To create mesh for bumper assembly, mesh element size is 6mm. To apply and study the different cases for the crash tube model. To study the effect of notches on the crash tube. To plot…

25 Jun 2023 09:25 PM IST

Assignment 4-RADIOSS Material Laws Challenge

AIM: To run crash analysis on the given model by applying different materials laws available in Radioss and post-process the results Objective: To carry out simulations of the given starter files and compare the results. There shall be 7 cases (according to given parameters) and they are to be compared primarily via animations…

20 Jun 2023 08:27 PM IST

Related Courses

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.