Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Underbody Coating

UNDERBODY COATING OBJECTIVE : To learn about underbody coating in the view of automobile and other general parts, also why underbody coating, types of under bodycoating in brief. INTRODUCTION : An undercoat is used after a primer. It is used to…

DHANASEKARAN A

updated on 18 May 2022

UNDERBODY COATING

OBJECTIVE :

To learn about underbody coating in the view of automobile and other general parts, also why underbody coating, types of under bodycoating in brief.

INTRODUCTION :

An undercoat is used after a primer. It is used to fill any minor imperfections to create a smooth, even-coloured surface ready for the application of the topcoat. An undercoat also assists to lighten a surface when changing from a dark to a pale colour.

Underbody coating is usually a dense cladding (often based on rubber) applied uniformly to the undercarriage of the automobile. It is normally sprayed or painted on when the car is just out of the dealership and is clean. But even if you are getting the undercoating applied after a couple of years, it's fine too. This is because it can prevent further damage to the undercarriage.

The main purpose of undercoating is to check rust especially in the body components like frame rails along with other exposed metal parts. Underbody coating can also reduce wear and tear.

BEFORE COATING

AFTER COATING

WHY UNDERBODY COATING :

Underbody coating provides long term protection from corrosion to car's underbody. It also protects parts like internal body panels, frame rails and other inner cavities that are not physically accessible but are prone to corrosion.

CHEMICAL COMPOSITION OF UNDERBODY COATING PAINT :

The composition shows a very good resistance against chipping, temperature and corrosion, whereas it is also fully recyclable without the risk of formation of toxic or otherwise dangerous compounds in contrast with the presently applied PVC-plastisol undercoating compositions.

Rubberized Undercoating

Asphalt-Based Undercoating

Asphalt-based undercoating offers a higher level of protection suitable for large trucks, recreational vehicles, and heavy machinery. It’s formulated with some bits of rubberized material to aid in noise reduction. It offers extra protection against chips and moisture but is not paintable and, therefore, only suitable for undercarriages.

Polyurethane Undercoating

Polyurethane coating is easy to apply and works by sealing up cracks and seams. The compound displaces salt and moisture and protects the unoxidized metal from rust. It’s often sold in canisters that are ready to preload into an application gun. It, however, requires some surface prep work before application, like degreasing, and applying an etching primer to the bare metal.

Wax or Paraffin-Based Undercoating

Wax or paraffin-based undercoating sprays are the cheapest and quickest options available. However, their results don’t last long, and you may have to apply a fresh coat after only a few months. In addition, the wax isn’t very adhesive on a metal surface. Its main advantage is that it seeps quickly into cracks and seams, and offers moderate protective properties against moisture.

AUTOMOTIVE UNDERBODY COATING PROCESS

Modern automotive coating methods consists of five main steps.

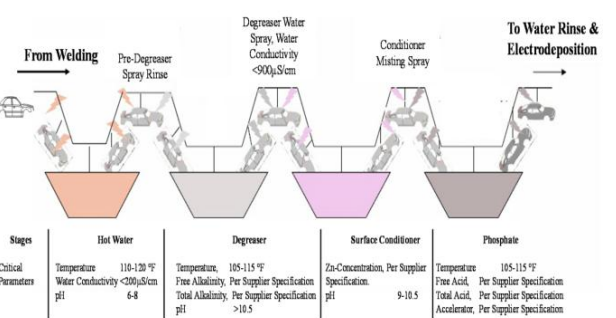

PRETREATMENT

ELETRODEPOSITION

E-coating involves dipping automobile bodies into the coating solution & passing an electric current through the body & the liquid ED paint solution. Because of the charged nature of this coating process, the ED paint penetrates into places a spray would not reach.

During operation, a mixture of resin, binder, & a paste containing the pigments is fed into the ED tank. The automobile body is lowered into the tank, & an electric current applied; the solution in the tank consists of 80-90% deionised water & 10-20% paint solids.The resin is the backbone of the final paint film & provides corrosion protection, durability, & toughness. Pigments are used to provide color & gloss.

After E-coat, the automobile body enters a bake oven, in which heating & keeping at a temperature of 160_C for 10 min causes film curing to promote maximum performance properties. The oven temperature & heating time primarily enchance chip resistance & film adhesion to the body corrosion protected is affected less by these conditions. Because surface roughness influences the smoothness & brilliance of the topcoat, some sanding of the surface is usually performed to remove or eliminate defects before the body enters the next application step.

A common challenge in the cureent E-coating process is that of water spots that contaminate coated surfaces. If water spots are present, they have removed sanding. Hence, it is necessary to use well-deionoised water & routinely monitor its conductivity. Alternstely, operators also add surfactants or ultrafiltrates to the water rinse zone to eliminate or manage water spots.

RUST-PROOF MATERIALS: SEALER/PVC

The third step is underbody coating & seam sealing using PVC. Fig.4 displays the lower door sections & rocker panel locations where PVC or urethanes are applied as an anti-chipping protection, & shows the cross section of this layer with respect to the other coatings on the body parts.

During this third step, it is also typical to apply a soft tip primer coat that improves the chipping resistance . This layer is applied to the front edge of the hood , which is an area prone to chipping shock, using a high elastic resin that resides between the ED & primer coats. Also, during the third step, the radiator supports, wheel housing, & under rar areas of the body are coated with a relatively dull black pigment called a blackout coating.

PRIMER

The fourth coating step is the primer. It can be water-borne, solvent-borne, or a powder. The primer fills & smoothes minor imperfections & scratches that may be created during prior steps & by the intermediate sanding or grinding used to remove small imperfections. It also provides additional protection against corrosion & maximizes adhesion between it & the E-coat & basecoat; thereby, the primer incrases paint durability.

Primer coating operations in an automobile assembly plant are usually implemented in three stages: Interior coating, Exterior coating, & then cutting in an oven. Manual spray painting is used for the interior coating of the doors, engine compartment, & luggage or trunk space. Some of the areas are not sprayed with basecoat. It is important that are primer color matches the basecoat to be able to impart uniform coating appearances between interior & exterior coats.

TOP COAT

The final step in the body coating process is to apply the topcoat, which consists of two layers the basecoat & clearcoat.

Base coat

It contains the primary coloring pigments. As part of the topcoat, the basecoat is third layer added to the car after the primer & before the clearcoat. It imparts the automobiles color; roughly 40,000 base coat color are known today , & approximately 1000 new colors are added to this list each year. Three different types of basecoats are used for automobiles, including solvent-borne medium solids (MS), solvent-borne high solids (HS), & water-borne.

Clear coat

The final coating on an automobile surface is the clearcoa; it provides durability, environmental etch, & scratch resistance to the overall coating. It protects against damage such as fading that is caused by UV rays from the sun & imparts a gloss & depth that otherwise are not as vivid. The clearcoat also makes repairs & maintenance easier. Environmental etch is an appearance issue associated with the formation of permanent water spots or nonremovable marks from bird droppings, tree resin, or other chemicals after contact with an automobiles surface. The physical damage resulting from etchi=ng is associated with a localized loss of material & deformation or pitting of the clarcoat surface.

PROS OF UNDERBODY COATING

- Undercoating are the protection it provides to the carriage of your vehicle.

- If you live in an area where salt and sand are used on the roadways in cold weather, these materials can be corrosive to your vehicle. Undercoating gives you an extra layer of protection against rust and corrosion, protecting your car.

- Even vehicles in warmer climates gain protection as debris is repelled and kept away from eating at the vehicle.

- It will extend the life of your vehicle.

- It can be applied to damaged areas.

- It may help to reduce interior noise.

CONS OF UNDERBODY COATING

- Undercoating will work best on new vehicles that have not been exposed to road conditions.

- A used vehicle may already have residue on the bottom of the car or even have spots of rust and corrosion.

- Undercoating will not help you if corrosion already exists and the corrosion needs to be removed first before it can be applied, which can be expensive for you.

- It adds weight to the vehicle.

- An undercoating is not impervious to damage.

- It must be reapplied every 3 to 5 years for the best results.

CONCLUSION :

The current report gave a semi-comprehensive & up-to-date review of these new processes & coating technologies, also a deep learn about underbody coating.

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by DHANASEKARAN A (8)

Week 9 - Challenge 2 - Switch Bezel Design

Tooling Axis Creation Take the class A surface Extract the bottom face and create the Origin Point Choose the Line command and make the axis normal to the Extracted surface. But in the bisection method, there are some errors during the draft analysis of the sidewall. Select the YZ plane and position…

27 Jun 2023 10:25 AM IST

Week 9 - Challenge 1 - Base Bracket Design

METHOD FOR DRAFT ANALYSIS - First I checked the possible direction for the draft analysis in my case the z-direction was the best possible way to take the draft analysis, then I created the dummy tooling axis for the reference of x,y,z-direction.then took a plane in refrence to yz-plane and took a intersection in…

24 Jun 2023 05:37 PM IST

Underbody Coating

UNDERBODY COATING OBJECTIVE : To learn about underbody coating in the view of automobile and other general parts, also why underbody coating, types of under bodycoating in brief. INTRODUCTION : An undercoat is used after a primer. It is used to…

18 May 2022 06:33 PM IST

Benchmarking

BENCHMARKING OBJECTIVE : …

18 May 2022 11:27 AM IST

Related Courses

0 Hours of Content

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.