Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Project 2 - Modeling of 3 phase Induction Motor Drive

This project is focused towards electric vehicle application using an Induction Motor. Student will have to take following steps for a successful model: 1.Model 3 Phase Inverter using Simulink (model the parasitic as well) with a switching frequency of 10Khz using 3 phase Squirrel Cage Induction motor, using V/F method,…

Nagaraj Krishna Naik

updated on 29 Mar 2023

This project is focused towards electric vehicle application using an Induction Motor. Student will have to take following steps for a successful model:

1.Model 3 Phase Inverter using Simulink (model the parasitic as well) with a switching frequency of 10Khz using 3 phase Squirrel Cage Induction motor, using V/F method, open loop

Design Parameters:

- Power = 100 HP

- DC Voltage = 800 V

- Output Voltage = 460 VRMS – line to line

- Initial Speed = 1500 RPM

- Final Speed = 1000 RPM

- Initial Load Torque = 10 Nm

- Final Torque=20 Nm

- Torque Step Time = 0.1 secs

For Induction Motor model – use Asynchronous Machine from Simulink with Squirrel Cage Preset Model – 05 , for 100HP Motor

For back emf to speed relation, assume a linear rate from 0.25 to 1, with speed changing from 500 RPM to 2000 RPM

Plot speed, stator voltage (line to line) and frequency.

Plot stator line voltage, phase current

Open Loop V/F Control:

The open loop V/F control of an induction motor is the most common method of speed control because of its simplicity and these types of motors are widely used in industry. Traditionally, induction motors have been used with open loop 50Hz power supplies for constant speed applications. For adjustable speed drive applications, frequency control is natural. However, voltage is required to be proportional to frequency so that the stator flux

Ѱs=Ѵs/ωs

Remains constant if the stator resistance is neglected. The power circuit consists of a diode rectifier with a single or three-phase ac supply, filter, and PWM voltage-fed inverter. Ideally, no feedback signals are required for this control scheme.

The PWM converter is merged with the inverter block. Some problems encountered in the operation of this open loop drive are the following:

The speed of the motor cannot be controlled precisely, because the rotor speed will be slightly less than the synchronous speed, and in this scheme, the stator frequency and hence the synchronous speed is the only control variable.

The slip speed, being the difference between the synchronous speed and the electrical rotor speed, cannot be maintained, as the rotor speed is not measured in this scheme. This can lead to operation in the unstable region of the torque-speed characteristics.

The effect of the above can make the stator currents exceed the rated current by a large amount thus endangering the inverter-converter combination

These problems are to be suppressed by having an outer loop in the induction motor drive, in which the actual rotor speed is compared with its commanded value, and the error is processed through a controller usually a PI controller and a limiter is used to obtain the slip-speed command.

Three phase inverter with motor:

Three-phase inverter is used to change the DC voltage to three-phase AC supply. Generally, these are used in high power and variable frequency drive applications.

Generally, the three arms of this inverter will be delayed with 120 degrees angle to generate a 3 phase AC supply.

The switches used in the inverter have 50% of ratio and switching can be occurred after every 60 degrees angle. The switches like S1, S2, S3, S4, S5, and S6 will complement each other. In this, three inverters with single-phase are placed across a similar DC source. The pole voltages within the three-phase inverter are equivalent to the pole voltages within the half-bridge inverter with a single phase.

Simulink model:

This model consists three major blocks

i)SVPWM pulse generator,

ii)3 phase inverter driver

iii)squirrel cage induction motor

given parameters are loaded to the model as follows

SVPWM pulse generator:

For this SPWM (v/f) control, speed is taken as input in a step block. the step output is given to the gain block to multiply with the p/120.

Ns = 120f/P

f = Ns*P/120.

By using the above formula frequency is measured.

Speed is taken as input in the step block with an initial speed of 1500 rpm and a final of 1000 rpm as given in the design parameters.

For the time input a clock block is used. And these output values are given to a bus selector block.

The bus selector output signal is given to the MATLAB function block and the phase voltages are measured by using the below formulae:

In Fcn block above formulas impleted as follows

for R phase

for Y phase

For B phase

carier signal:

By comparing each phase output and repeating sequence with the relational operator the gate signals are generated and a not gate is connected for negative operation gate signal then these signals are given to scope to visualize the response.

Gate pulses from SVPWM stratergy is shown below

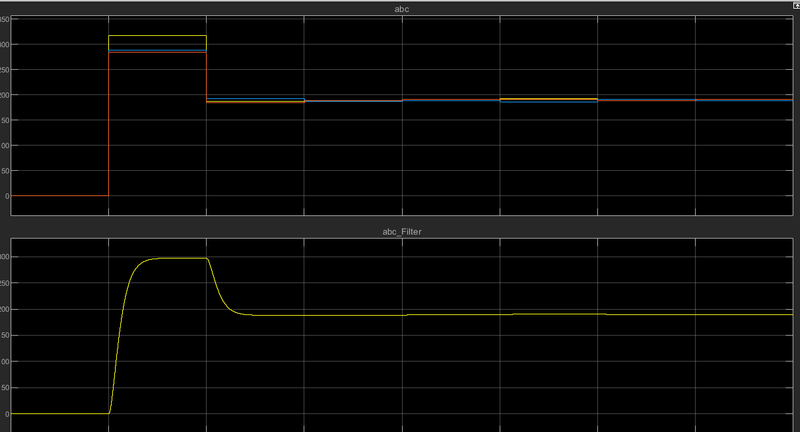

From the below plot, the frequency is starting from 50 hz and at 0.4 secs the step fall to 33.33hz and is constant until 0.8 seconds.

ii)3 phase inverter:

In this subsystem, the 800V DC voltage source is taken as input. And connected to the IGBT switches. Three legs with six IGBT switches are used in this inverter. Each leg has two switches for positive and negative operation. Each leg on the phase is connected to the load. A resistive load of 1ohm/phase is used in this model to measure the line-to-line and phase voltages. And three output connections are taken and given as input supply induction motor.

stator line to line voltage is shown below

stator line voltage is shown below

iii) Squirrel cage induction motor:

In this subsystem, the induction motor with torque input is observed.

For the induction motor is connected to the 3-phase inverter with an input supply.

And for the motor toque input a step block with torque input values are taken.

In the motor block pre-set model, no:5 is taken as mentioned in the project description. To observe the motor stator current, speed, and torque parameters a bus selector block is connected to the Induction motor measurement block and parameters are selected. Then the stator current and torque are given to scope, the rotor speed is multiplied with a gain block 60/2*pi, and it was given to scope.

From the below plot, the phase current is at the top of the plot, the speed is in the middle, and the torque is at the bottom. The speed is increased and reaches 1500 rpm at 0.4 seconds. Then the speed is decreased to 1000 rpm and maintained constant till 0.8 seconds.

______________________________________________________

2. Use the 3 phase inductor motor theory to derive the transfer function of 3 phase Induction Motor

The transfer function of an Induction motor is obtained from the Mathematical modeling of an induction motor and by taking all the required basic Equations.

r1=resistance of Stator

X1=Stator leakage reactance

I1=stator current

Rc=shunt branch resistance

Xm=magnetizing reactance

Ie=per phase no-load current

I2=Rotor current

I2'=Rotor Current per phase referred to as stator

X2'=standstill rotor reactance referred to as stator

r2'=rotor resistance referred to as stator

V1=Stator Voltage

E1=stator induced emf

s=slip

__________________________________________________________________

3. Model 3 phase induction motor with a 3 phase inverter using Direct Torque control using an Average Model, Implement both torque and flux control to achieve desired power.

Design Parameters:

- Initial Speed = 0 RPM

- Flux Target = 2.5 webers

- DC Voltage = 500 V;

- Fundamental Frequency = 60 Hz

- Speed Step Time = 0.01 secs

- Determine fundamental speed based upon fundamental frequency

- Determine the switching sequence for direct torque control

- Moment of Inertia = 0.1 Kgm^2

- Load Torque Initial = 0 Nm

- Final Load Torque = 50 Nm

- Torque Step Time = 0.03 secs

Motor Parameters: (Create an Average Model)

- Stator Resistance = 0.5 Ohms

- Rotor Resistance = 0.2 Ohms

- Stator Leakage Inductance = 20 mH

- Rotor Leakage Inductance = 10 mH

- Magnetizing Inductance = 200 mH

- Number of Poles = 4

- Torque to Speed

Direct Torque Controller

Direct torque control (DTC) is a technique that allows you to instantaneously control the motor magnetic flux and its electromagnetic torque in a decoupled way. Controlling the torque directly permits accurate static and dynamic speed regulation. The main components of the DTC subsystem are:

- Flux and Torque Calculation — The stator flux linkage is estimated by integrating the stator voltages, and torque is calculated based on the estimated flux and the motor currents.

- Speed Regulator — The regulator compares the actual motor speed with the speed reference and generates the torque reference.

- Hysteresis Control — The calculated flux magnitude and torque are compared with the reference values. When the resulting flux or torque error crosses either the positive or negative hysteresis band value, a control signal is activated in order to correct the error.

- Optimal Switching — Pulses to the motor inverter are produced based on the control signals generated by the hysteresis control and the stator flux linkage position.

The figure below illustrates the strategy used to determine the best voltage vector when the flux linkage is located in sector 0.

The image shows four cases:

-

V3 is selected when the electromagnetic torque should be increased and the flux should stay unchanged. Selecting the V3 voltage vector speeds up the flux and thus applies an acceleration torque to the rotor while slightly decreasing the flux magnitude.

-

V2 is selected when the electromagnetic torque should be increased and the flux should be increased. Selecting the V2 voltage vector slightly speeds up the flux and increases its magnitude.

-

V6 is selected when the electromagnetic torque should be reduced and the flux should be increased. Selecting the V6 voltage vector slows down the flux and thus applies a deceleration torque to the rotor while increasing the flux magnitude.

-

V5 is selected when the electromagnetic torque should be reduced and the flux should stay unchanged. Selecting V5 the voltage vector applies a deceleration torque to the rotor and slightly decreases the flux magnitude. Note that voltage vectors V1 and V4 are not selected in sector 0. Using these two vectors would have too much negative impact on the desired flux value. Finally, to keep the torque and the flux unchanged, the null voltage vectors V0 or V7 are selected.

When the flux linkage vector moves to sector 1, the selected voltage vectors become V4 for case 1, V3 for case 2, V1 for case 3, and V6 for case 4, and vectors V2 and V5 are not used. This 60 degree shift in the voltage vectors happens each time the flux linkage vector enters a new sector.

Simulink model:

The electrical energy is supplied by a three-phase AC/DC diode rectifier connected to a 500V dc source. The DC bus is connected to a three-phase, two-level converter. This converter generates the variable voltage and frequency required for the variable-speed operation of the 150 HP induction motor.

An inverter-fed induction motor drive can be controlled through various techniques depending on the application, desired performance, and controller design complexity. Commonly used schemes are scalar control (V/Hz control or open loop flux control) or vector control (field-oriented control or direct torque control). This example uses a hysteresis-based direct torque control (DTC) technique.

Set points as per the given design requirement:

Machine with given parameters and those are loaded in program

program with all necessary paramters:

Two-level converter:

Direct torque control method:

The Inverter will works the Signals commands what we generated by using the Direct Torque method

Direct torque control (DTC) is a technique that allows you to instantaneously control the motor magnetic flux and its electromagnetic torque in a decoupled way. Controlling the torque directly permits accurate static and dynamic speed regulation.

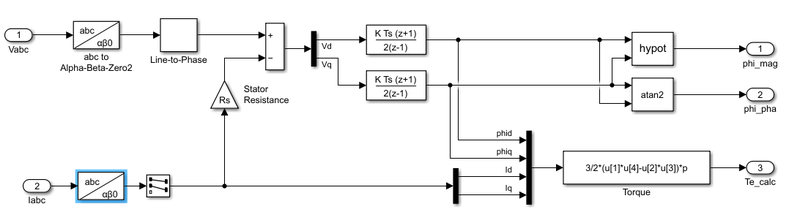

Flux and Torque Calculation:-

The stator flux linkage is estimated by integrating the stator voltages, and torque is calculated based on the estimated flux and the motor currents.

>>this Flux and Torque calculation is desin by using the abc to Alpha-Beta-Zero block are send to the transfer fucntion block.

>> from this two abc to Alpha-Beta-Zero blocks we are created the three output signals ,Those are Phase magnitude phase angle and torques output.

Speed Regulator:-

The regulator compares the actual motor speed with the speed reference and generates the torque reference.

>>This block implements a speed regulator using an ant-windup PI controller.

>>From this Pi controllwer we are using the logical operation block as Or gate

>>after getting the signals we are sending these signals to relational operation block to get the Signals as per the requirements.

Hysteresis Control:-

The calculated flux magnitude and torque are compared with the reference values. When the resulting flux or torque error crosses either the positive or negative hysteresis band value, a control signal is activated in order to correct the error.

>>this Blcok is totally implemented by using the Saturation blocks for both torque and flux cobtrolling the at the output side from this blcok.

Optimal Switching:-

Pulses to the motor inverter are produced based on the control signals generated by the hysteresis control and the stator flux linkage position.

>>Based on the space vector specified, the block generates pulses for a two-level three-phase converter.

>>Based on the order number coming from the couple(T) & flux (phi) hysteresis controls, and on the sector number (flux position), the block determines the required voltage space vector (0-7).

after Completion of this Controll blcok modeling the Gate pulses are send to the two level Converter gate terminal.

In this way we get the gate signal by using the Controll og DIRECT tOrque Controll Method.

Determining fundamental speed based upon fundamental frequency:

speed Ns = 120 * f / P

fundamental frequency (F) = 60Hz

number of poles P = 4

Fundamental speed Ns = 120 * 60 / 4

Fundamental speed N = 1800RPM

Switching sequence for direct torque control:

Results:

_1680062382.png)

In this model after placing all the given values we were able to give only 600RPM as reference speed.If we give more than 600 the model won't track that reference and also the value gets ringing with ripple of kW.

in this model we gave contant 2.5*phi_n weber flux and that is got tracked by model

Output power:

By running the model with 600RPM we are getting almost 3kW power

_1680062424.png)

conclusion:

The Three Phase induction motor Drive is modeled and controlled using both the V/F control method and the Direct Torque Control Method and also the Transfer Function of the Induction motor based on the Equivalent Circuit is determined.

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Nagaraj Krishna Naik (18)

Project 2 - Modeling of 3 phase Induction Motor Drive

This project is focused towards electric vehicle application using an Induction Motor. Student will have to take following steps for a successful model: 1.Model 3 Phase Inverter using Simulink (model the parasitic as well) with a switching frequency of 10Khz using 3 phase Squirrel Cage Induction motor, using V/F method,…

29 Mar 2023 05:36 AM IST

Project 1 - Loss calculation for a DC/DC converter-MATLAB

Extending the learned lessons in previous module, you will be diving into another power electronics concept on your own. Design of boost converter, and calculating the loss of different components including power switching device and deriving efficiency of boost converter. This is applicable in power supply industry, electric…

25 Mar 2023 11:24 AM IST

Project 2

Using MATLAB/simulink and the drive cycle from the attached excel sheet, find- The max heat generation of the battery The SOC of the battery at 2 *104second of the battery operation Time Time Step Battery Current 00:00.4 0.1 -0.9632 00:00.5 0.2 -0.952 00:00.6 0.3 -0.9072 00:00.7 0.4 -0.9632 00:00.8 0.5 -1.0304…

20 Feb 2023 11:21 AM IST

Project 1

1. Design a battery pack for a car roughly 150 Kw with 120 V. Use 3500 mAh 3.6V nominal NMC chemistry cell. a. Design the battery pack configuration. b. Draw the BMS topology for this battery pack. Aim: To design the battery pack with the capacity 150Kw 120V by using 3500mAh 3.6V. And BMS topology for…

20 Feb 2023 05:43 AM IST

Related Courses

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.