Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Battery Thermal Management System Simulation

AIM The aim of this project is to simulate the flow inside a Battery Thermal Management System OBJECTIVES The main objectives are as follows Excel Calculator for Volumetric heat generation source Run the case for different mesh sizes - 12,8,6 and 4 mm Effect of element length on accuracy of results EXCEL CALCULATOR…

ANURAG BHARADWAJ

updated on 25 Sep 2020

AIM

The aim of this project is to simulate the flow inside a Battery Thermal Management System

OBJECTIVES

The main objectives are as follows

- Excel Calculator for Volumetric heat generation source

- Run the case for different mesh sizes - 12,8,6 and 4 mm

- Effect of element length on accuracy of results

EXCEL CALCULATOR

Since an Amp Hour (Ah) is a measure of charge (measured in "Coulombs") whereas a Joule is a measure of energy, you can't convert mAh to Joules without first knowing the voltage (Volts) a which the charge was transferred.

Given that voltage the conversion is just:

Charge (C) x Voltage (V) = Energy (J)

and,

Current (A) x time (seconds) = Charge (C)

To find the mAh to Joule conversion we first find the charge in a mAh.

mA means 1/1000 of an Amp for an hour and there are 60 x 60 = 3600 seconds per hour. So,

1mAh = 0.001 Amps x 3600 seconds = 3.6 Coulombs of charge.

Choosing 1 Volts for the voltage, we can now convert mAh to Joules.

3.6 (C) x 1 (V) = 3.6 (J)

We say at 1 Volts, 1mAh of charge equals 3.6 Joules of energy. This is a handy value for mAh to Joule conversions.

For any voltage, mAh X voltage x 3.6 = Joules of energy.

For example. A 7.2 Volt battery that delivers 100 mAh of charge has delivered,

100 x 7.2 x 3.6 = 2592 Joules of energy.

As we saw above, since a mAh is 1/1000 of an Ah, to convert Ah (amp hours) to Joules just use 1000 x 3.6 = 3600 as the conversion factor instead of 3.6.

An Amp Hour (Ah) is a measure of charge (measured in "Coulombs") whereas a Watt Hour (Wh) is a measure of energy. The two are related by voltage. So a 36 V battery stores twice the energy (Wh) of an 18 V battery.

When only an Ah specification is given it is understood that the voltage that determines the energy this represents is that of the battery (storage device).

In summary, the energy (measured in "Joules") stored in a 36 V, 15 Ah (15,000 mAh) battery is 36x15= 540 "Volt-Amp-hours" or Watt - hours. Where a Volt-Amp-hour (Wh) is 3600 Joules (J). So our battery has stored 1,944,000 Joules of energy!

That's pretty close to the ~2,110,000 Joules in a stick of dynamite? A good reason to respect storage batteries!

BATTERY THERMAL MANAGMENT SYSTEM SIMULATION-CASE 1

Now for the simulation of BTMS we have to follow these steps

- Geometry

- Mesh

- Solution

- Setup

- Results

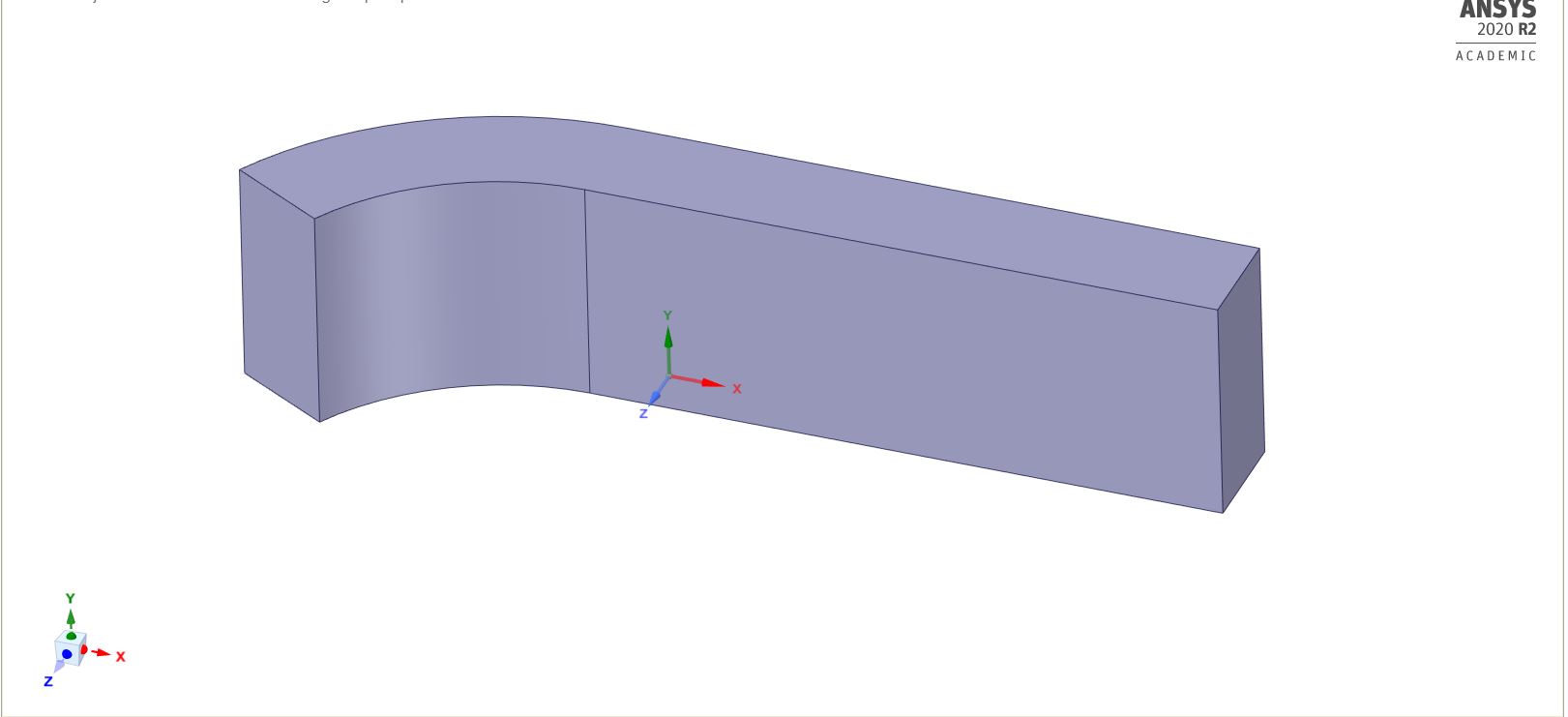

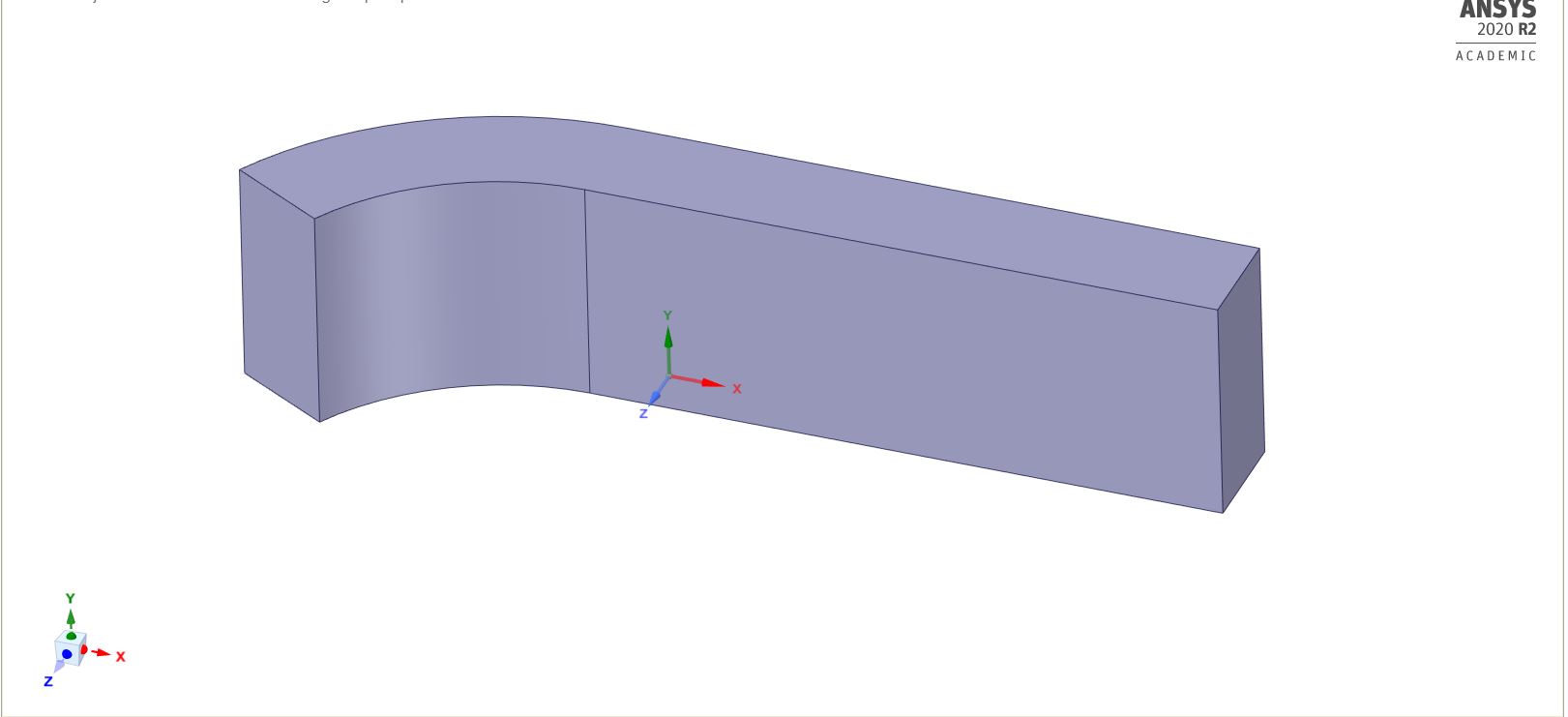

Geometry

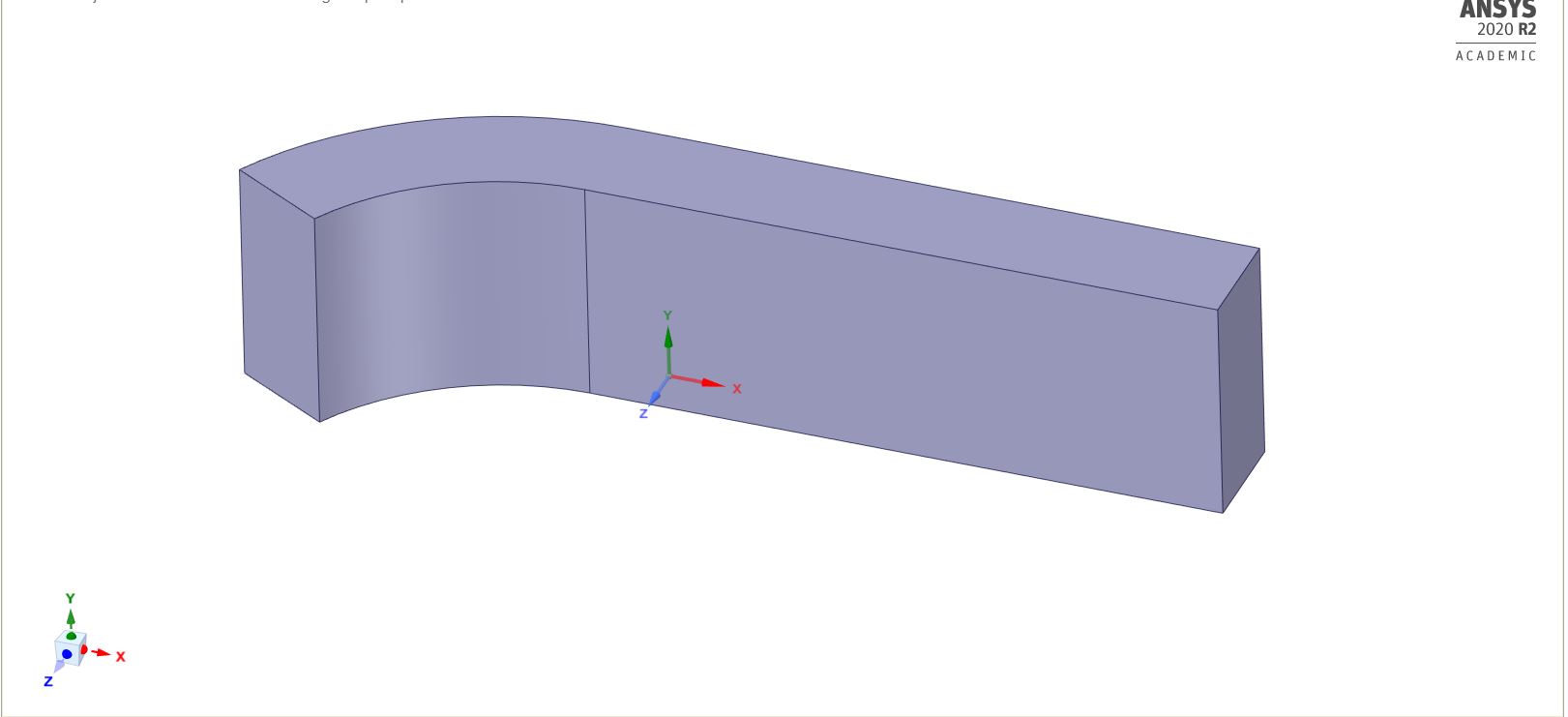

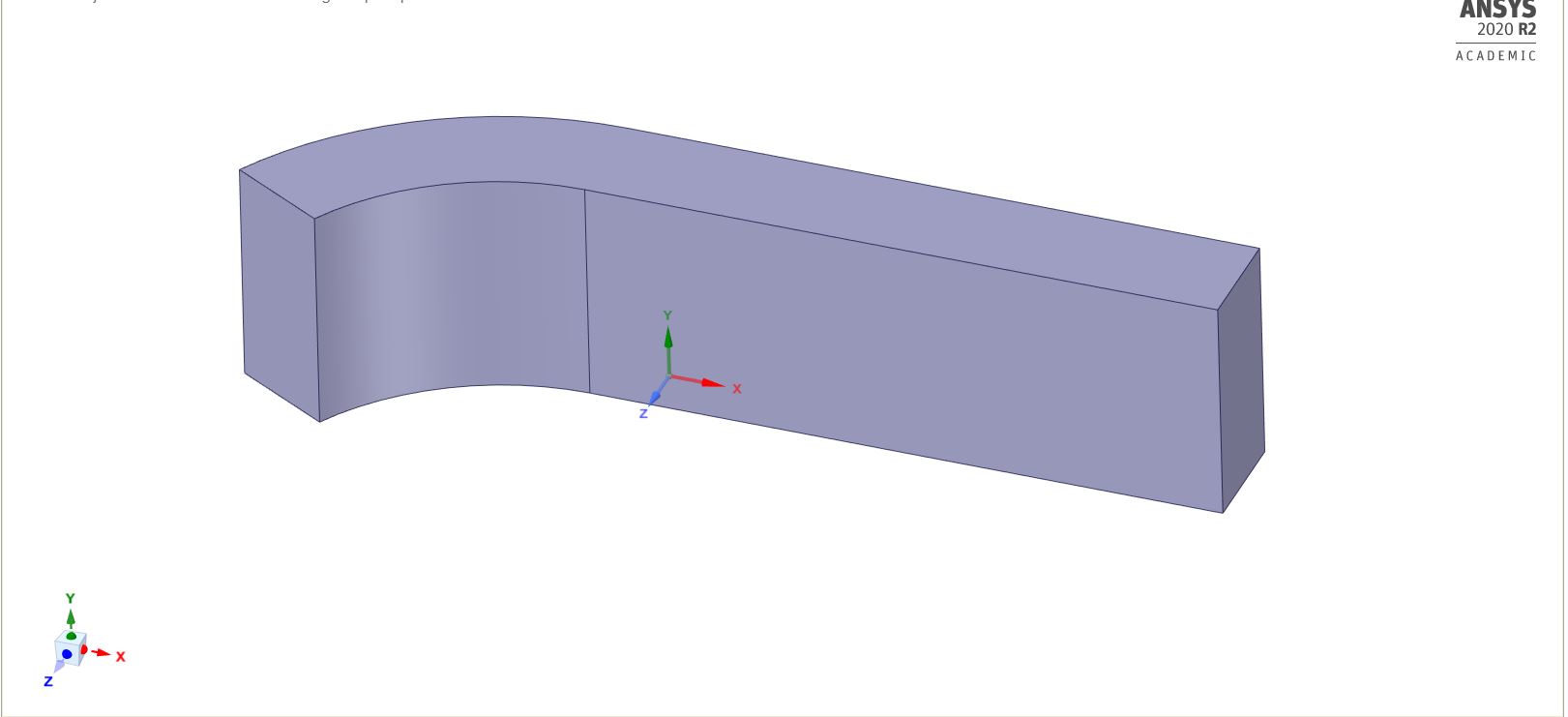

This is the CAD model of a made up BTMS which contains 5 cells which is enclosed in the fluid volume and air is cooling fluid which is being circulated around the battery.

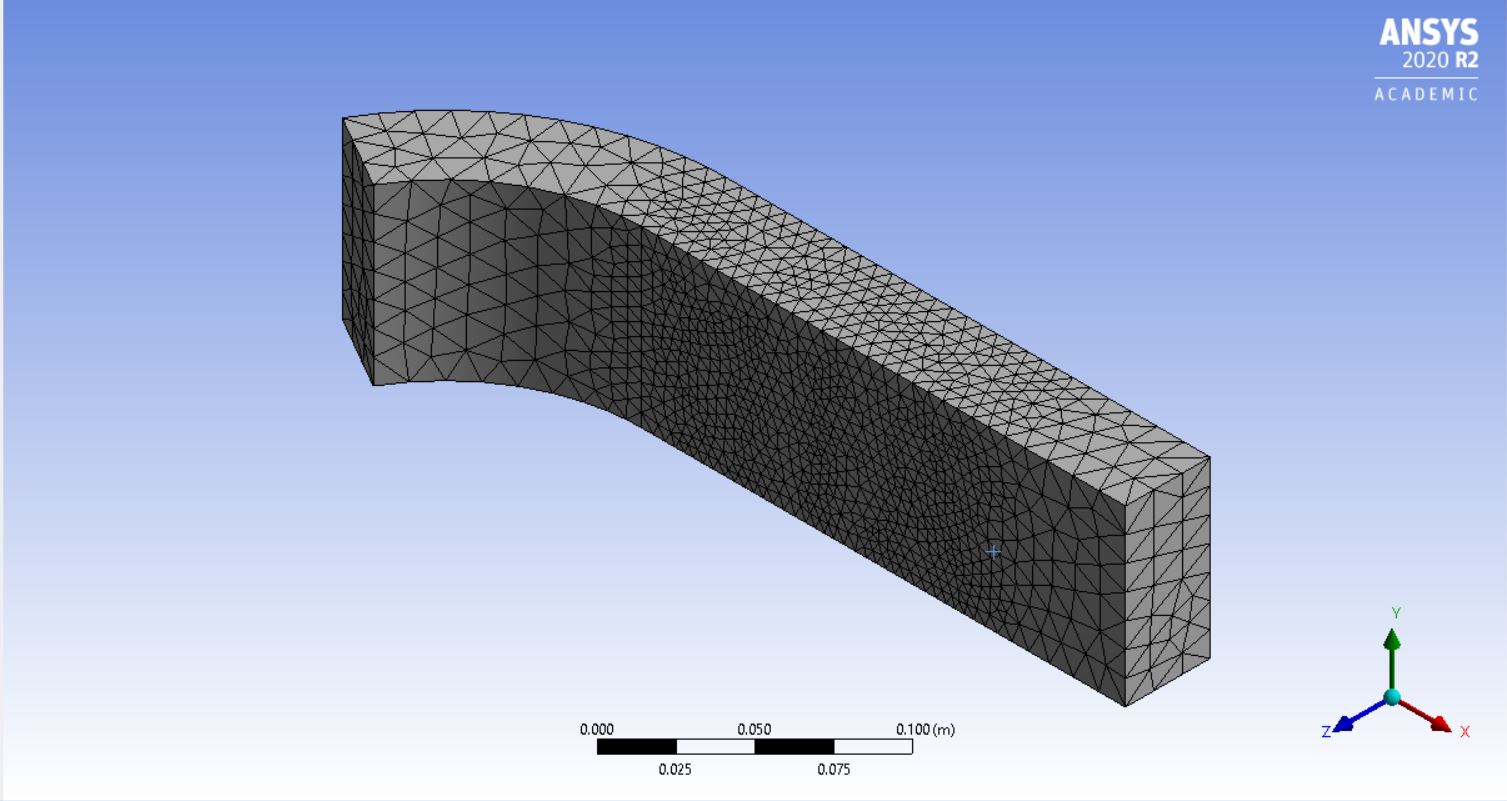

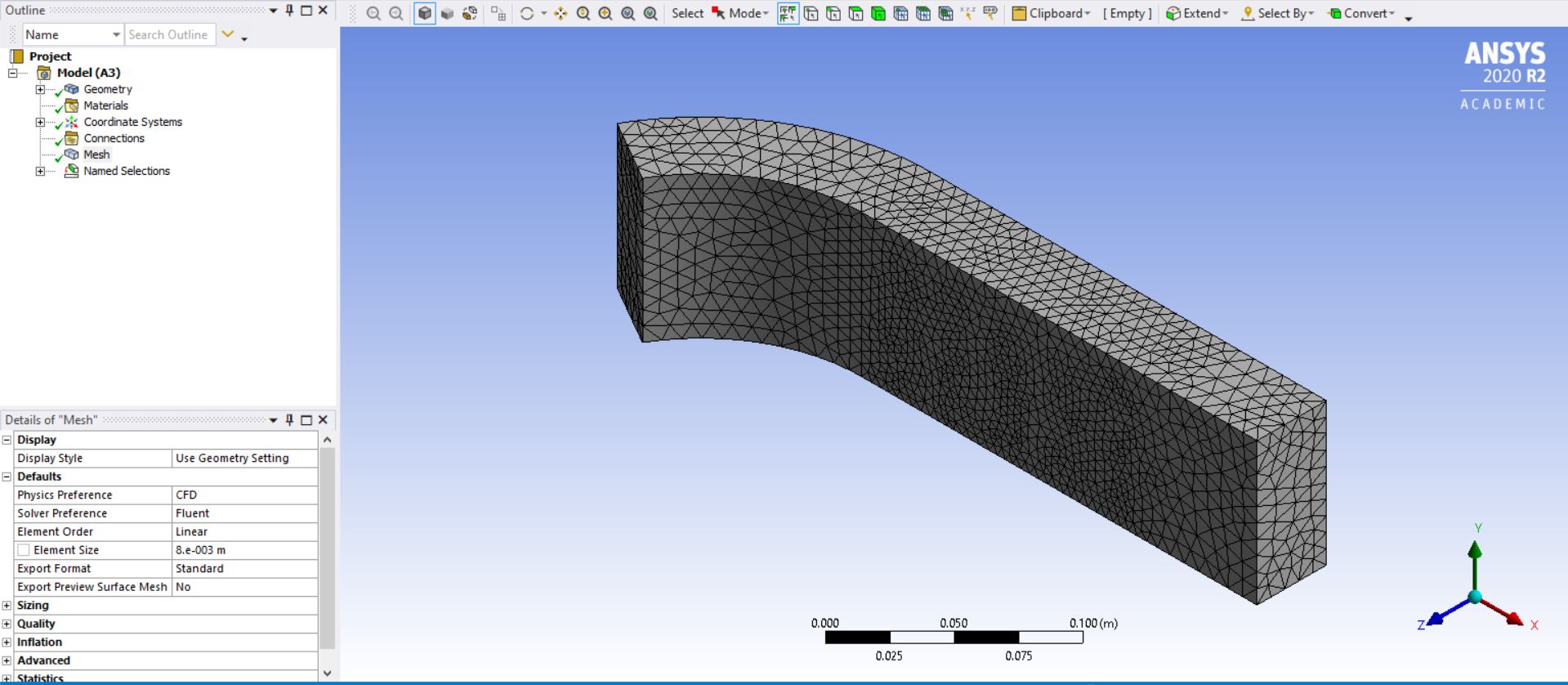

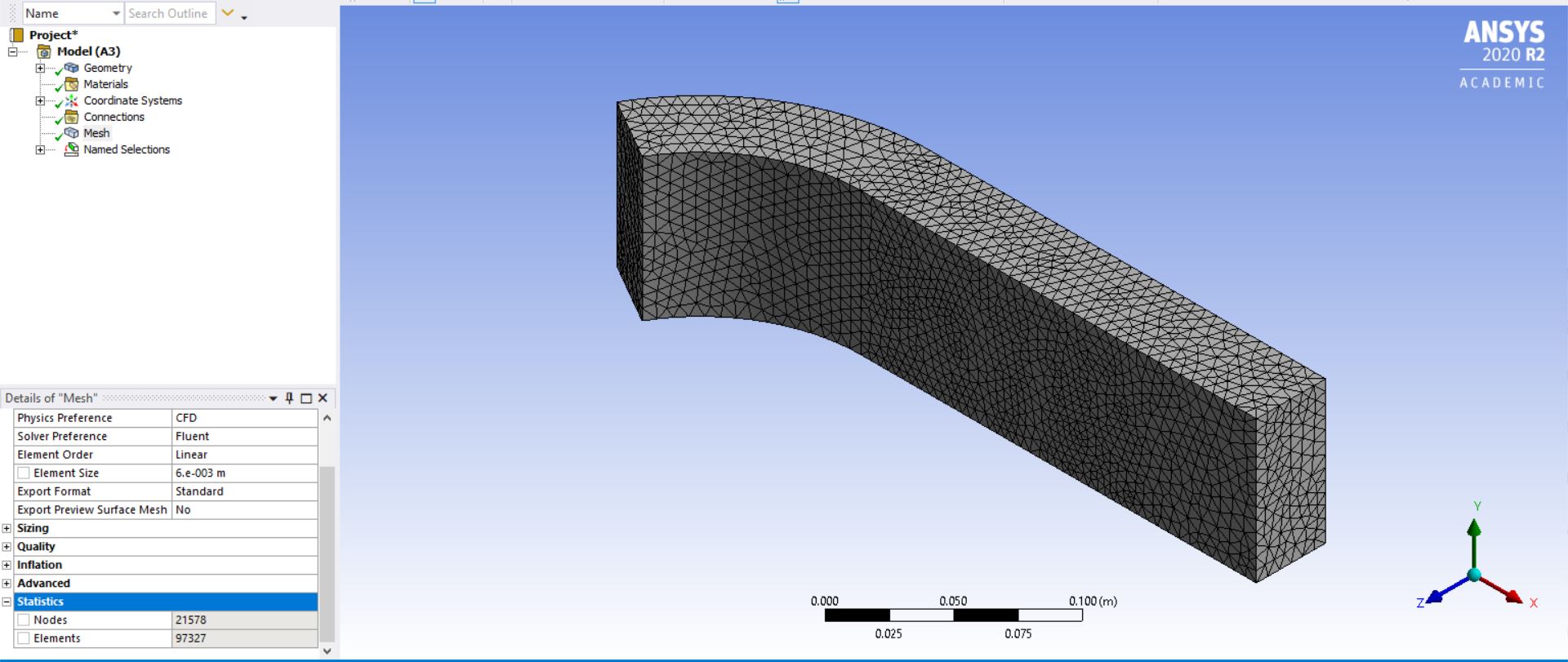

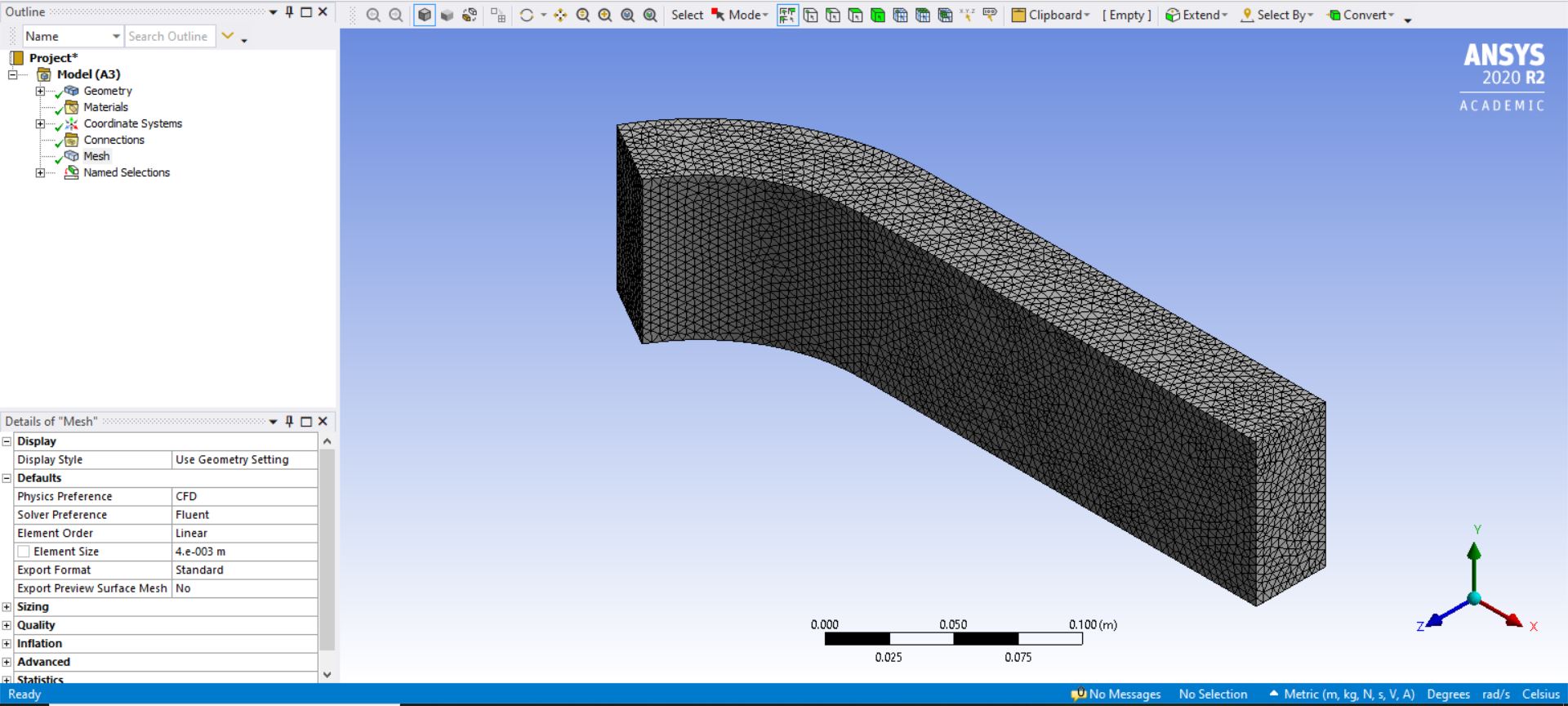

Mesh

Now here an element size of 12mm is used which takes the count of the number of elements to 85127 elements. The tetrahedral mesh is used for the fluid volume. But when we say that the cell is a solid zone it creates ordinary mesh.

Setup

- Solver-Density solver

- Solver state - Steady state

- turbulence Model - K-Epsilon Model

- Inlet Velocity = 4m/s

- Volumetric Heat source = 30000 W/m^3

- Outlet Pressure = 0 Pascals

While simulating the BTMS, it is not fine to use any solid material because the battery manufacturer would have specified the material that is being used for the battery cells. But for the simulation purpose it should be seen that the material should have certain thermal properties to conduct the heat easily to the cooling liquid in the battery pack

During the previous derivation of 1D heat energy balance equation we see the terms like thermal conductivity and heat generation term.

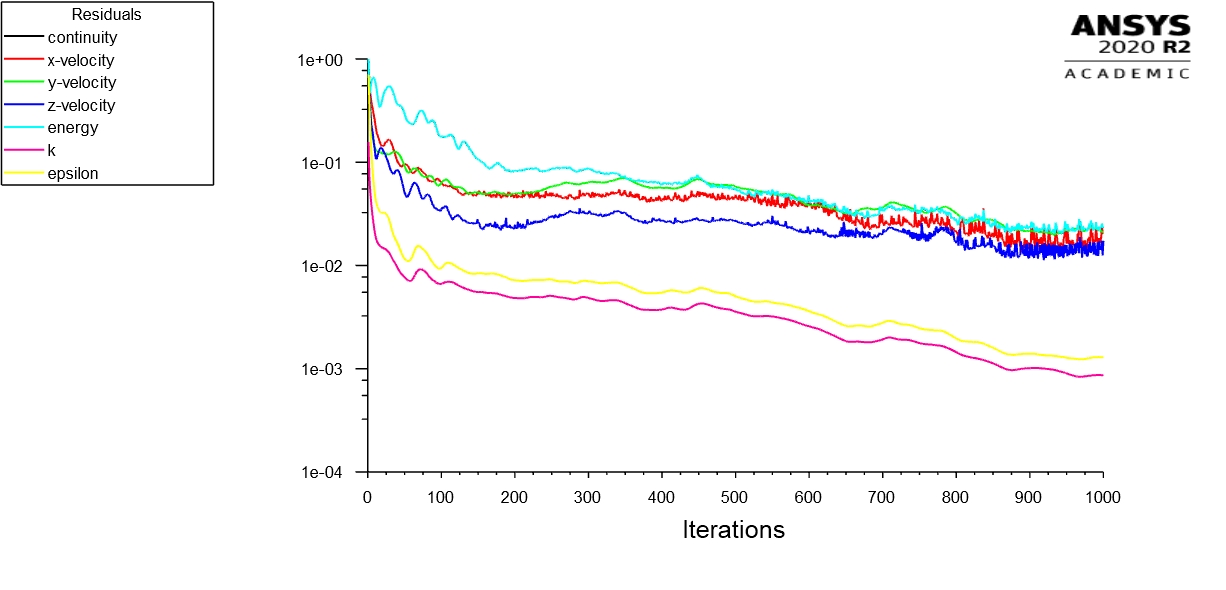

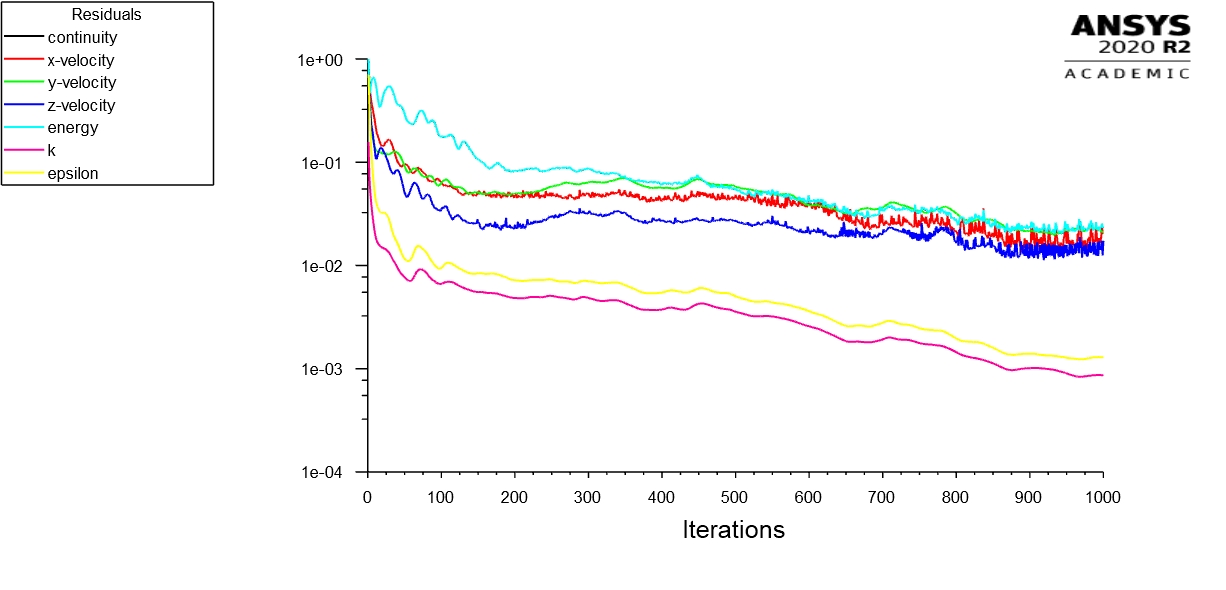

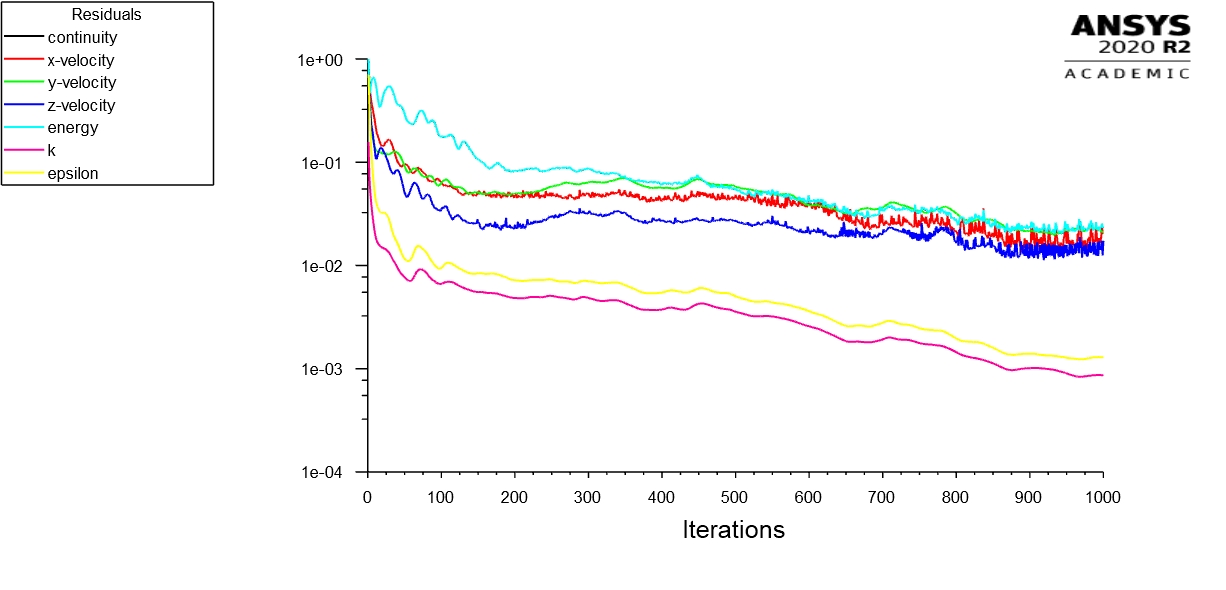

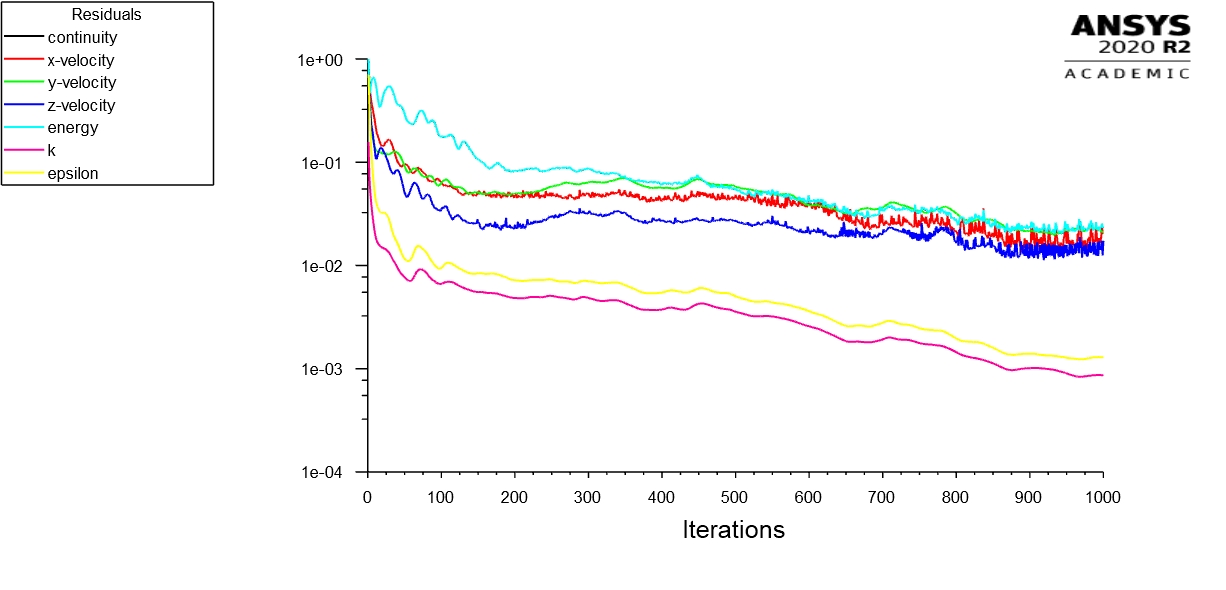

Residual Plot

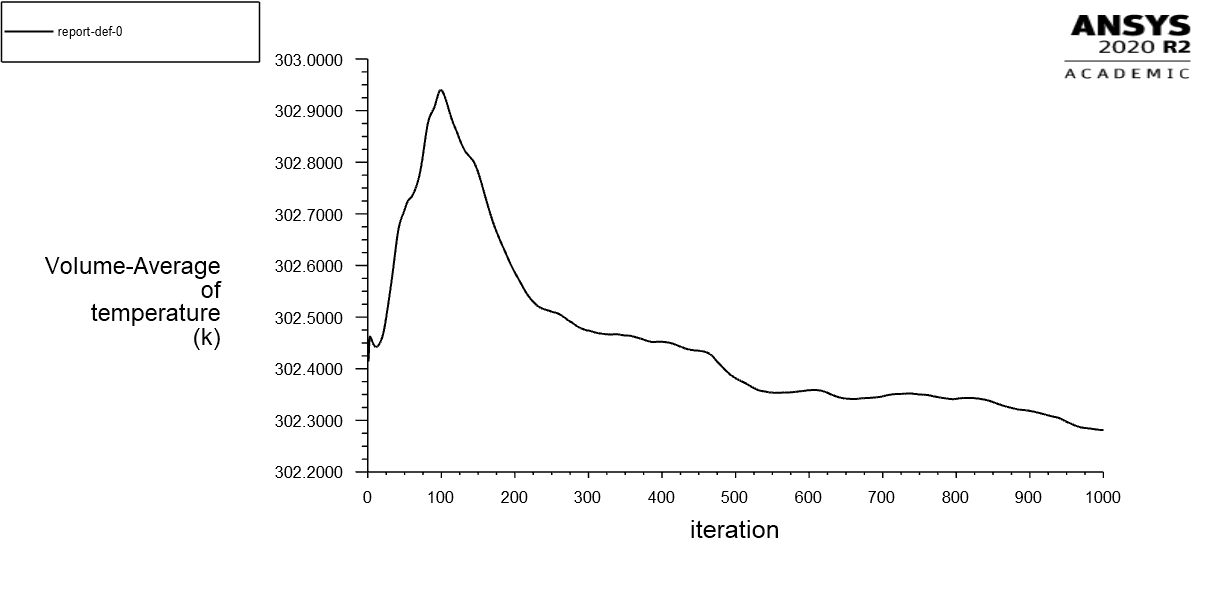

Now here the simulation was run for 1000 iterations and we observe that the solution has converged after 900 iterations

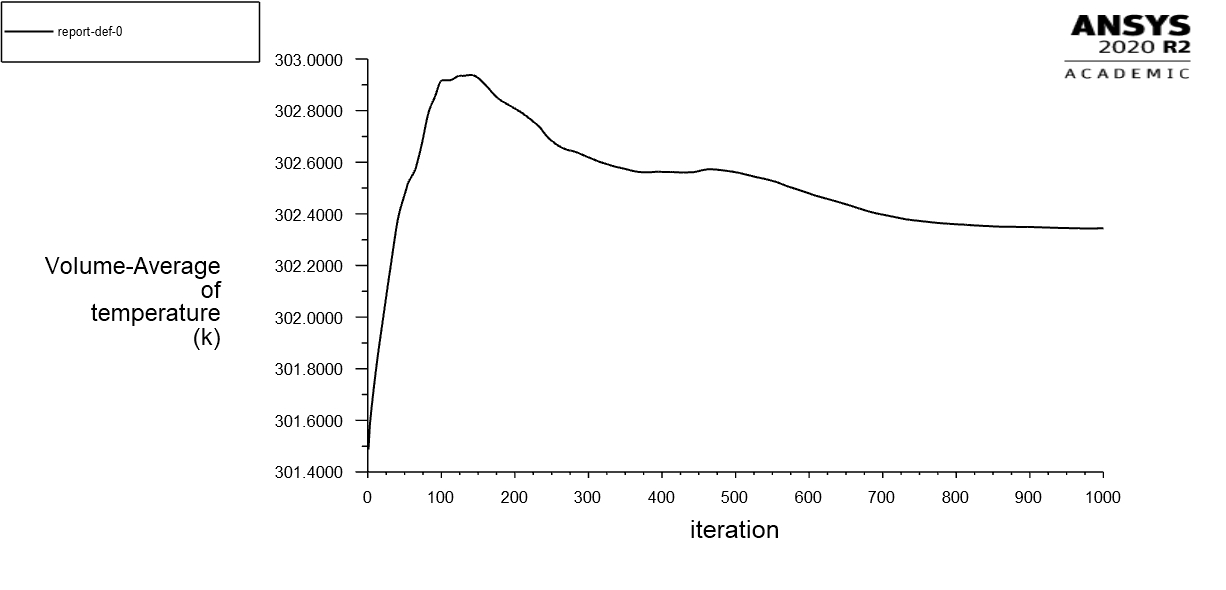

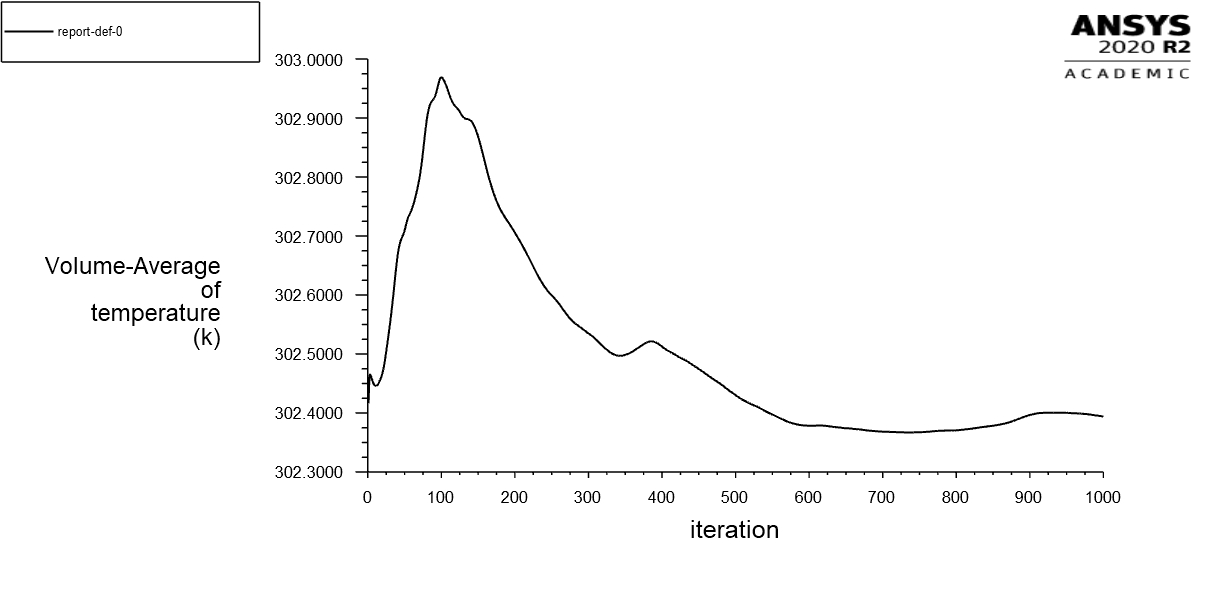

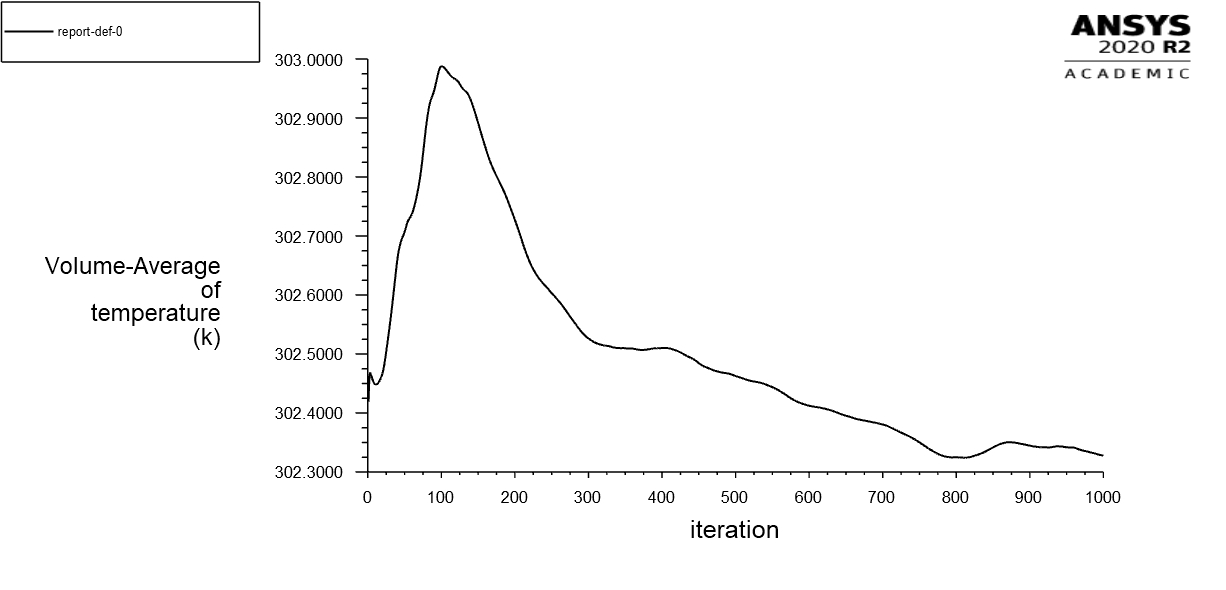

Volume Average Temperature plot

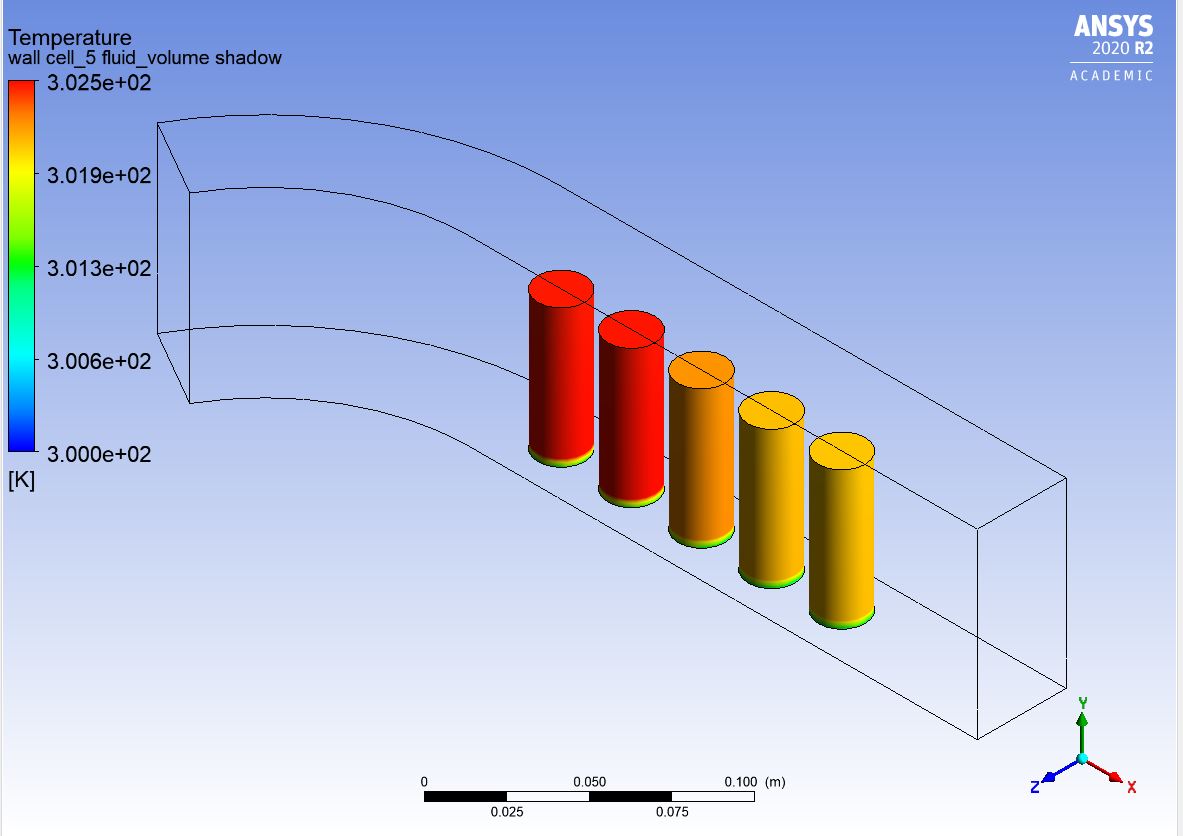

Results

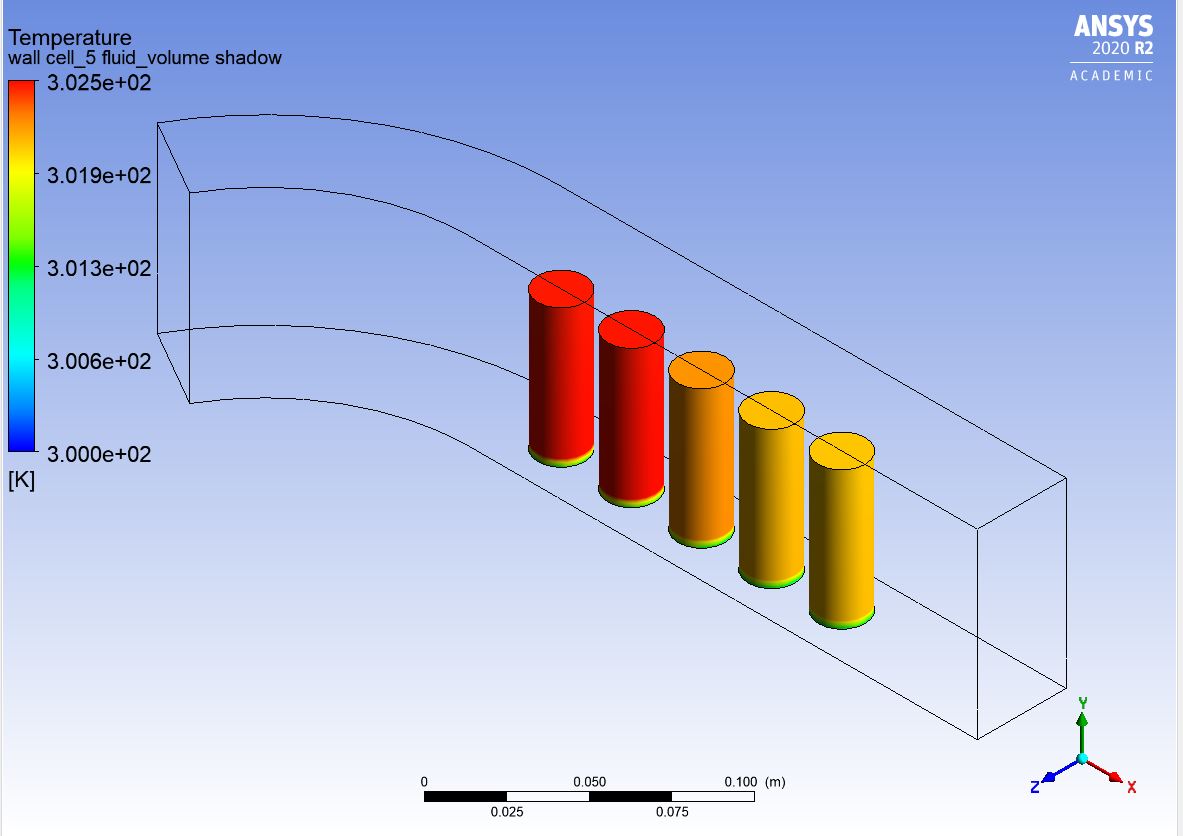

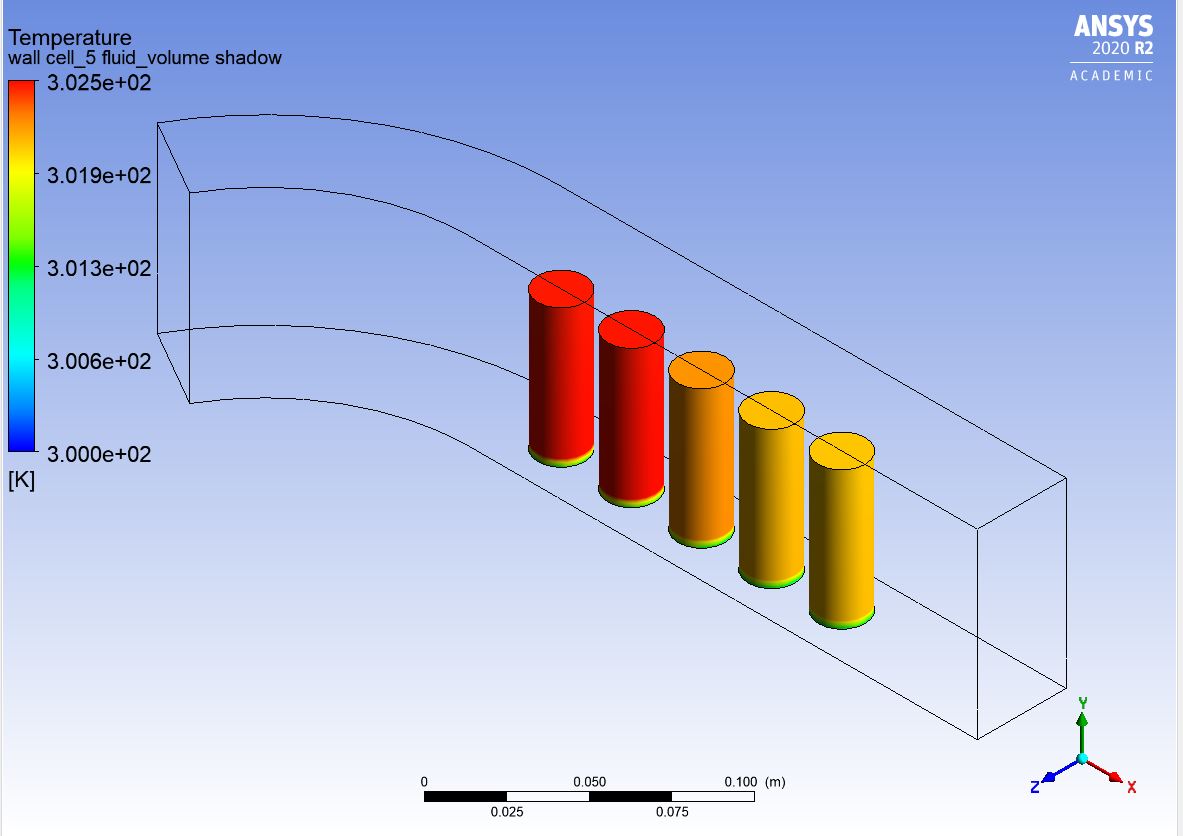

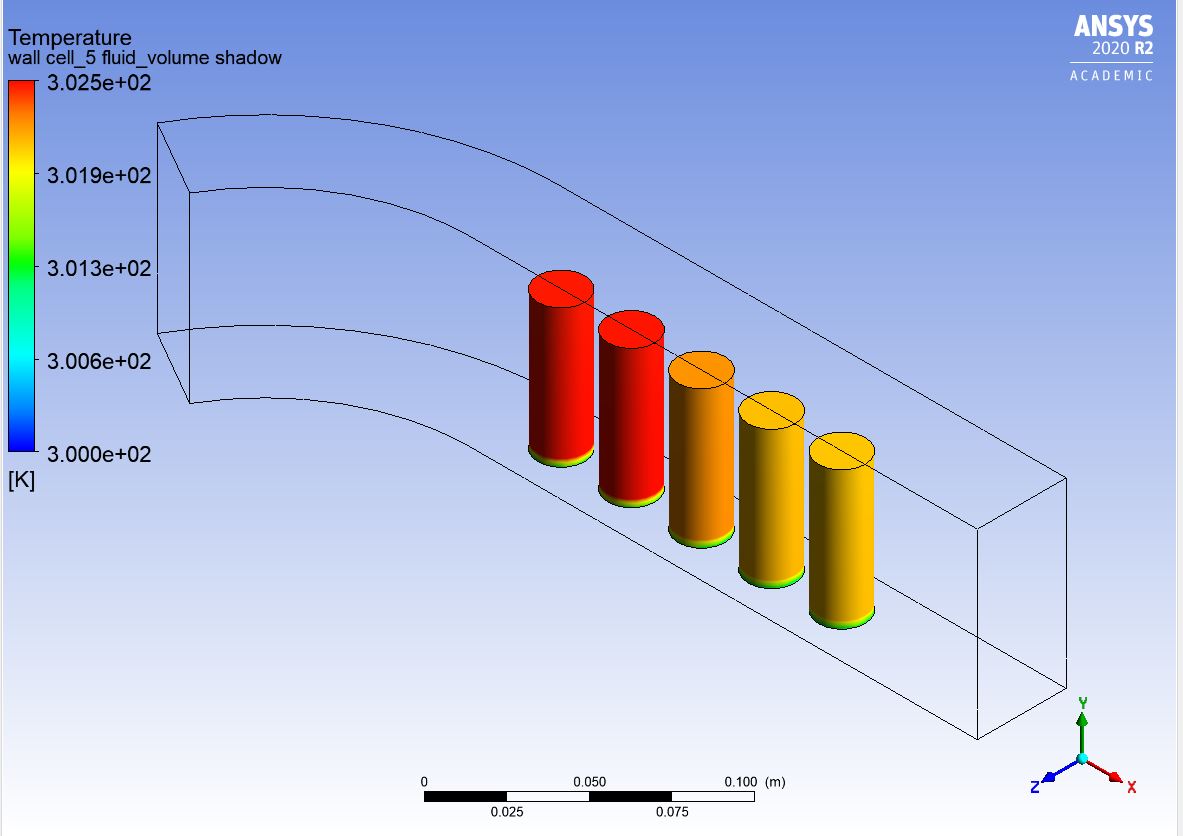

Temperature Contour of Cells

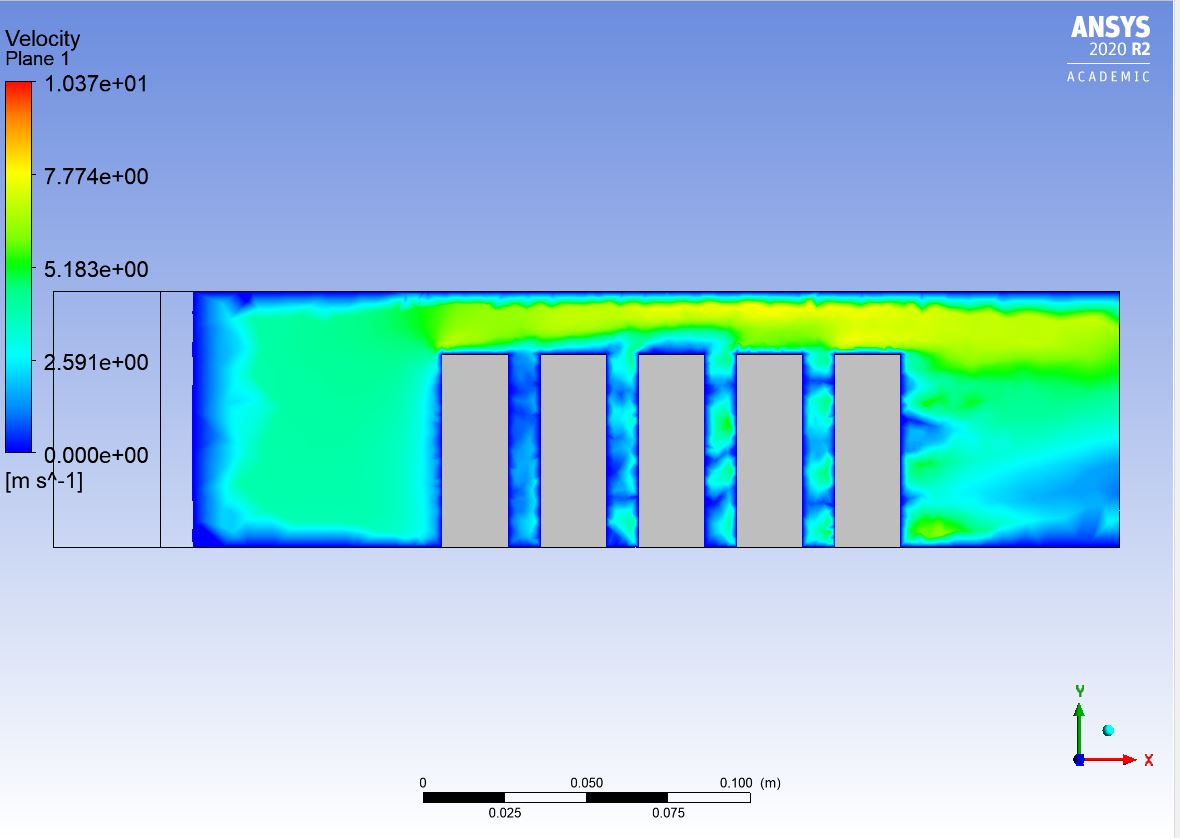

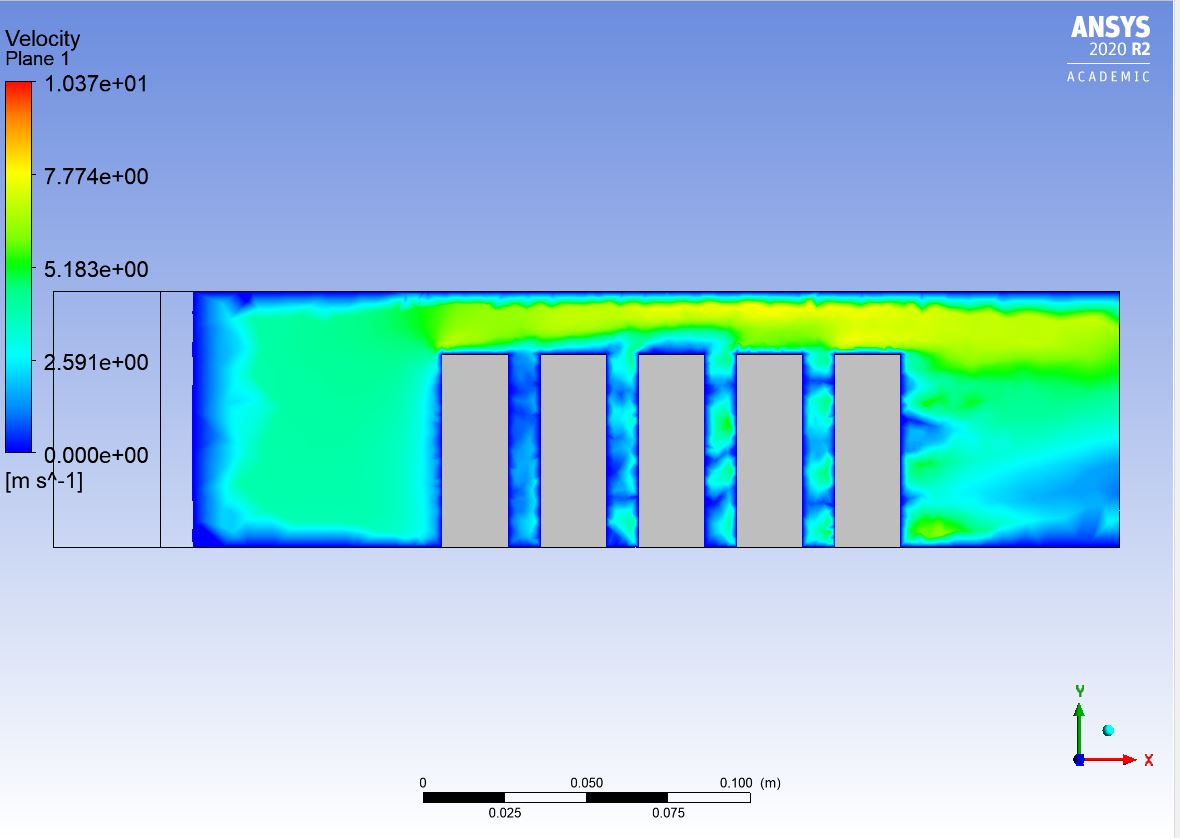

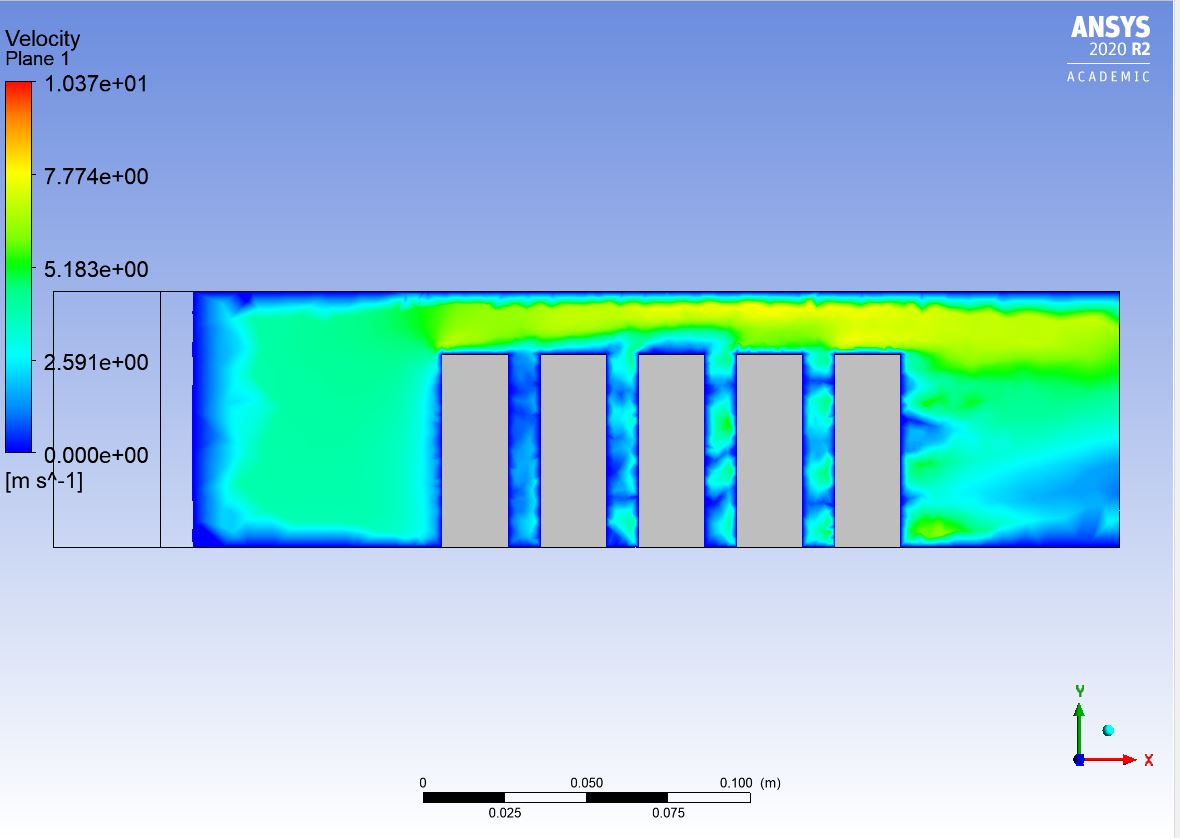

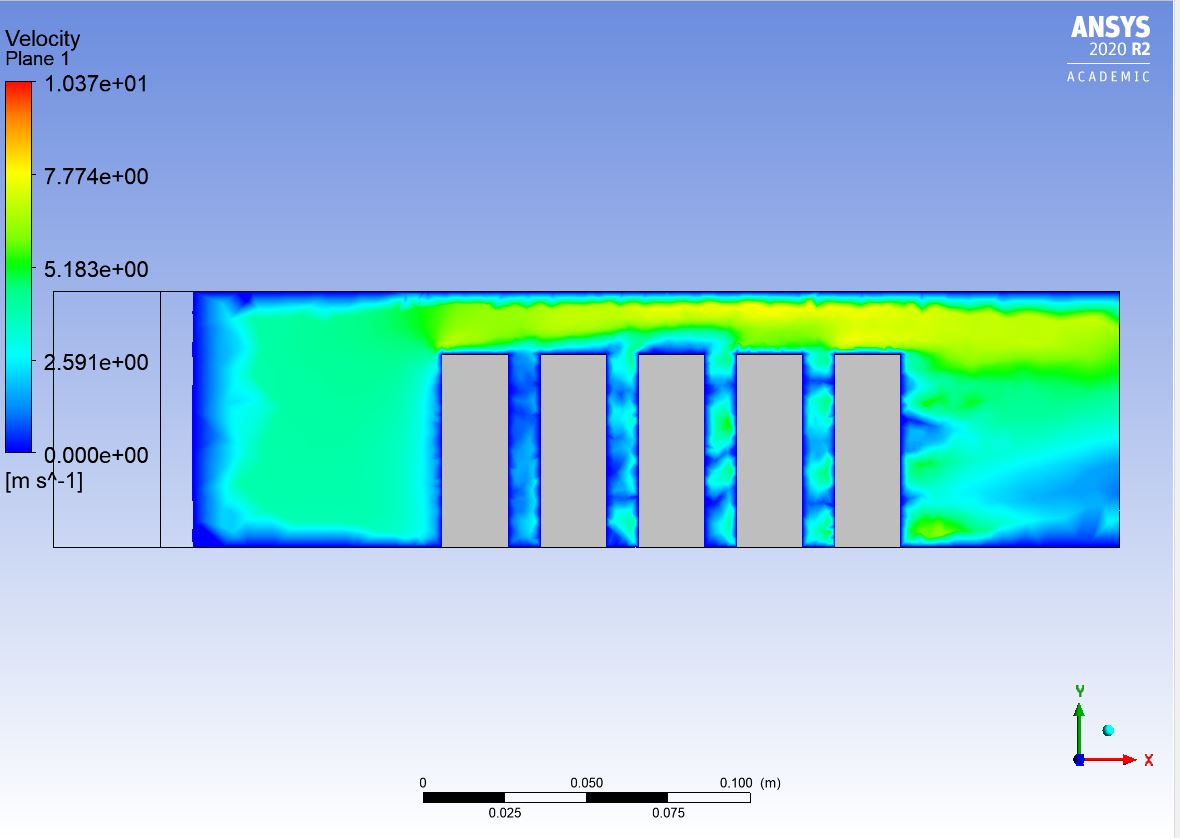

Velocity Contour Plot

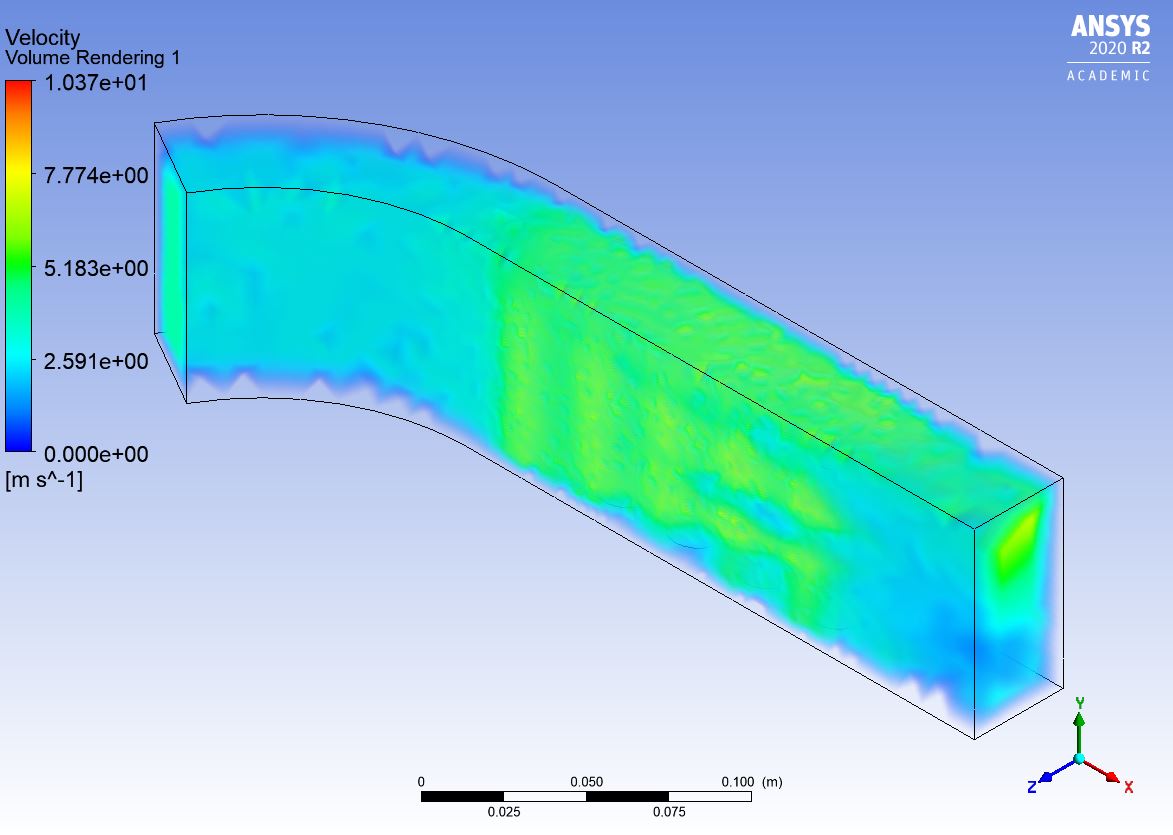

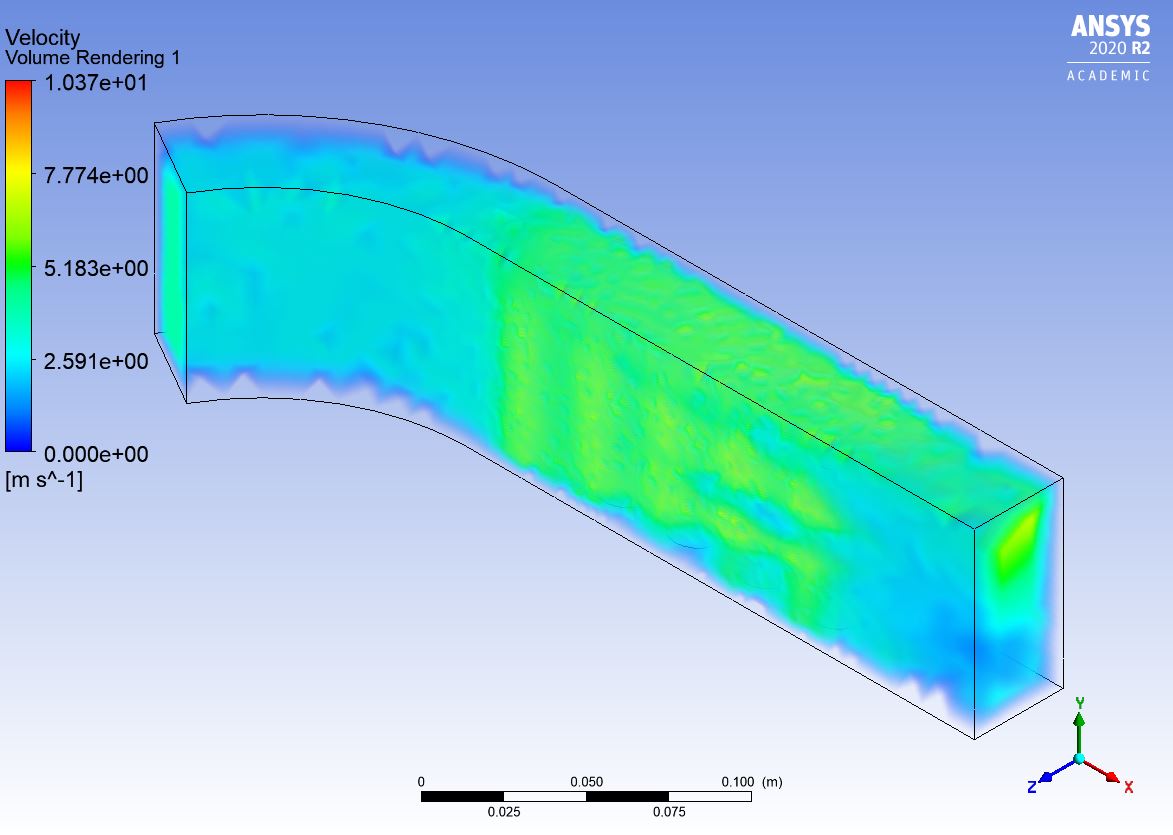

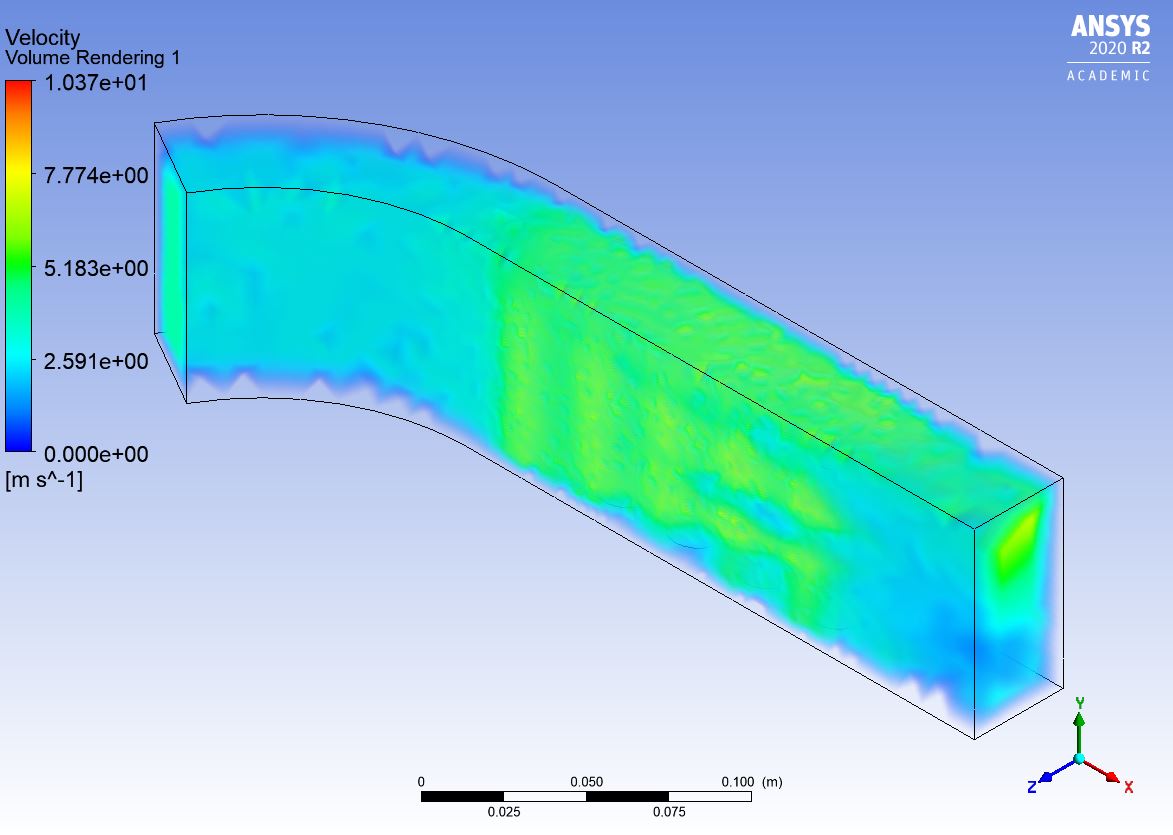

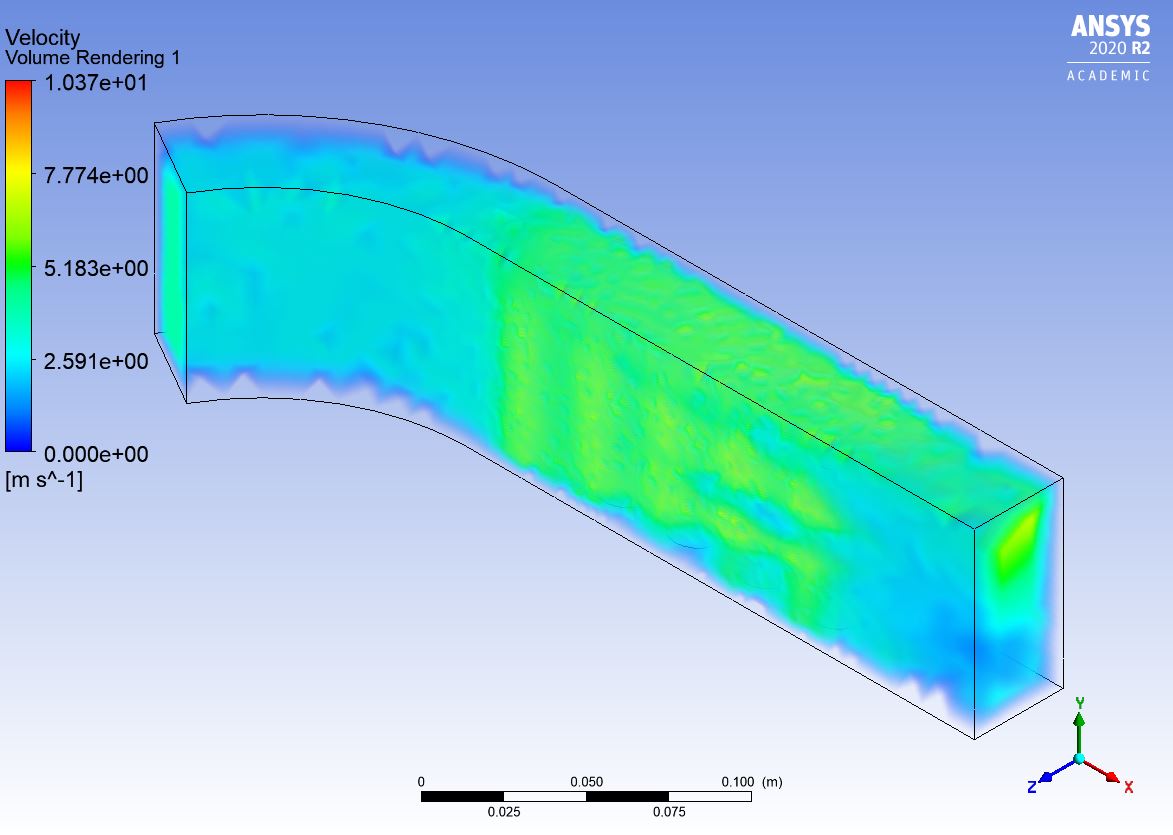

Velocity Volume Render

BATTERY THERMAL MANAGMENT SYSTEM SIMULATION-CASE 2

Now for the simulaton of BTMS we have to follow these steps

- Geometry

- Mesh

- Solution

- Setup

- Results

Geometry

This is the CAD model of a made up BTMS which contains 5 cells which is enclosed in the fluid volume and air is cooling fluid which is being circulated around the battery.

Mesh

Now here an element size of 8mm is used which takes the count of the number of elements to 85127 elements. The tetrahedral mesh is used for the fluid volume. But when we say that the cell is a solid zone it creates ordinary mesh.

Setup

- Solver-Density solver

- Solver state - Steady state

- turbulence Model - K-Epsilon Model

- Inlet Velocity = 4m/s

- Volumetric Heat source = 30000 W/m^3

- Outlet Pressure = 0 Pascals

While simulating the BTMS, it is not fine to use any solid material because the battery manufacturer would have specified the material that is being used for the battery cells. But for the simulation purpose it should be seen that the material should have certain thermal properties to conduct the heat easily to the cooling liquid in the battery pack

During the previous derivation of 1D heat energy balance equation we see the terms like thermal conductivity and heat generation term.

Residual Plot

Now here the simulation was run for 1000 iterations and we observe that the solution has converged after 900 iterations

Volume Average Temperature plot

Results

Temperature Contour of Cells

Velocity Contour Plot

Velocity Volume Render

BATTERY THERMAL MANAGMENT SYSTEM SIMULATION-CASE 3

Now for the simulaton of BTMS we have to follow these steps

- Geometry

- Mesh

- Solution

- Setup

- Results

Geometry

This is the CAD model of a made up BTMS which contains 5 cells which is enclosed in the fluid volume and air is cooling fluid which is being circulated around the battery.

Mesh

Now here an element size of 6mm is used which takes the count of the number of elements to 85127 elements. The tetrahedral mesh is used for the fluid volume. But when we say that the cell is a solid zone it creates ordinary mesh.

Setup

- Solver-Density solver

- Solver state - Steady state

- turbulence Model - K-Epsilon Model

- Inlet Velocity = 4m/s

- Volumetric Heat source = 30000 W/m^3

- Outlet Pressure = 0 Pascals

While simulating the BTMS, it is not fine to use any solid material because the battery manufacturer would have specified the material that is being used for the battery cells. But for the simulation purpose it should be seen that the material should have certain thermal properties to conduct the heat easily to the cooling liquid in the battery pack

During the previous derivation of 1D heat energy balance equation we see the terms like thermal conductivity and heat generation term.

Residual Plot

Now here the simulation was run for 1000 iterations and we observe that the solution has converged after 900 iterations

Volume Average Temperature plot

Results

Temperature Contour of Cells

Velocity Contour Plot

Velocity Volume Render

BATTERY THERMAL MANAGMENT SYSTEM SIMULATION-CASE 4

Now for the simulaton of BTMS we have to follow these steps

- Geometry

- Mesh

- Solution

- Setup

- Results

Geometry

This is the CAD model of a made up BTMS which contains 5 cells which is enclosed in the fluid volume and air is cooling fluid which is being circulated around the battery.

Mesh

Now here an element size of 4mm is used which takes the count of the number of elements to 85127 elements. The tetrahedral mesh is used for the fluid volume. But when we say that the cell is a solid zone it creates ordinary mesh.

Setup

- Solver-Density solver

- Solver state - Steady state

- turbulence Model - K-Epsilon Model

- Inlet Velocity = 4m/s

- Volumetric Heat source = 30000 W/m^3

- Outlet Pressure = 0 Pascals

While simulating the BTMS, it is not fine to use any solid material because the battery manufacturer would have specified the material that is being used for the battery cells. But for the simulation purpose it should be seen that the material should have certain thermal properties to conduct the heat easily to the cooling liquid in the battery pack

During the previous derivation of 1D heat energy balance equation we see the terms like thermal conductivity and heat generation term.

.

Residual Plot

Now here the simulation was run for 1000 iterations and we observe that the solution has converged after 900 iterations

Volume Average Temperature plot

Results

Temperature Contour of Cells

Velocity Contour Plot

Velocity Volume Render

SIMULATION ACCURACY

When we compare all the 4 cases of the residual plot, and the various contour plots, we can observe that if we refine the mesh to fine level we see an increase in the accuracy of the results. But after a certain mesh size the accuracy almost remains constant

CONCLUSION

- The flow over a BTMS is performed

- The heat generation source term was derived based on battery specifications

- The mesh size was varied and we see that there is a slight improvements in the results and plots

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by ANURAG BHARADWAJ (55)

Hybrid Vehicle Case Study

AIM The aim of this challenge is to simulate the hybrid vehicle model OBJECTIVES Simulation run of hybrid vehicle Increase the Vehicle mass by 50%. Increase the Drag coefficient by 5%. Comparison of the results HYBRID ELECTRIC VEHICLES A hybrid vehicle is one that uses two or more distinct types of power, such…

10 Sep 2021 02:28 PM IST

Week 11: FSAE Car Project

AIM The aim is to simulate the Aerodynamics Behaviour of FSAE Car OBJECTIVE ABCD Racing company is looking to perform Aero Simulations for their FSAE vehicle and they have hired you to do the job. The suspension team wants a detailed report on the total downforce on individual components. They have two races in this…

29 Aug 2021 08:15 AM IST

Week 10: Modeling and Simulation of flow around an Ahmed Body

AIM The aim of this validation project is to simulate and validate the flow over an Ahmed Body OBJECTIVES Creating the CAD file for the Ahmed body Making of virtual wind tunnel for the car Simulating the case and validation of results with experimental values AHMED BODY The Ahmed body was described originally by…

22 Aug 2021 12:40 PM IST

Flow over an NACA 2412 Airfoil

AIM The aim of this project is to simulate the flow over a NACA 2412 Airfoil OBJECTIVES Plot Coefficient of drag vs angle of attack Plot Lift Coefficient vs angle of attack Comparison of turbulence model results AIRFOIL An airfoil (American English) or aerofoil (British English) is the cross-sectional shape…

04 Aug 2021 04:01 PM IST

Related Courses

0 Hours of Content

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.